A Recession’s Impact on Manufacturing and What Economists Predict for the Future

Where does manufacturing stand amid a recession, and what impact does a recession have on the manufacturing industry?

If we look at what history shows us, there’s no doubt that a recession is tough on not only manufacturing processes but on every layer of our economy, all the way down to consumer behavior.

Manufacturers and consumers alike face the shift and strain of economic instability, and with the current state of our economy, it is safe to say the pressure is already present.

However, history also reveals that economic downturns are cyclic and are a natural part of the wax and wane of the market. Decision makers in the manufacturing industry can watch for tell-tale signs of recession indicators and identify patterns in the U.S. economy to be resilient, adaptable, and shift their processes to, say, 3D printing to safeguard their company’s financial future.

How Recessions Affect the Manufacturing Industry

At a Glance:

- Higher production costs

- Increase production wait times due to part, labor, and transport shortages

- Shocks in the supply chain, since most of the parts we use in the U.S. are sourced globally

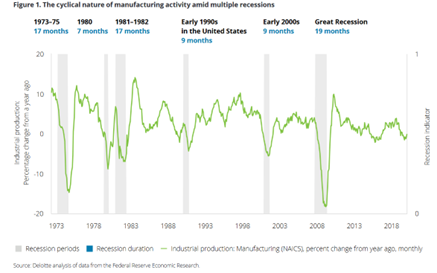

A recession can increase supply shortages and wait times for a subcomponent to complete an assembly. Economic data reveals that every time there’s a recession, there’s a huge drop in production followed by a huge upswing. In terms of future predictions, the sudden increase in production during a recession is a good sign that the recession has ended.

According to an article from Deloitte, the reason why the manufacturing industry is so sensitive to a recession lies in the hands of consumers. The average consumer prioritizes buying from industries that fuel basic human needs, such as food and healthcare, during an economic downturn. Conservative buying activity inadvertently affects manufacturing since demand dips.

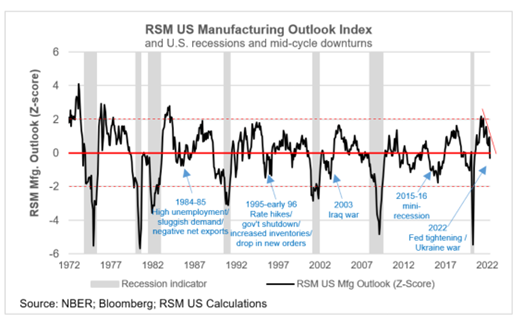

Additionally, right now in 2022, the U.S. tax auditing and consulting firm RSM has reported a recent sharp decline in the outlook of the U.S. manufacturing industry Z score. An industry’s Z score represents their confidence or uncertainty compared to normal conditions and is measured in the number of standard deviations. Positive Z scores represent industry confidence, and negative Z scores represent industry uncertainty.

Joseph Brusuelas, Chief Economist and Principal from RSM, states that the decline in industry sentiment (Z score) during the recent mini recession was due to interlinking problems like supply chain disruptions, overproduction of inventory, and talent shortages. As you can see from the graph, the U.S. manufacturing outlook is again declining in 2022 due to federal tightening and cross-border effects of the Ukraine/Russia War.

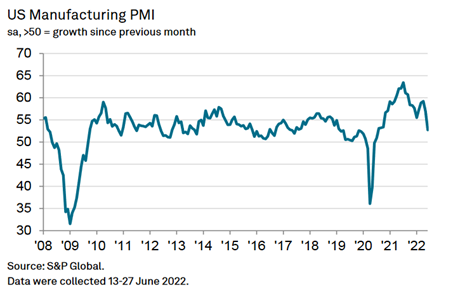

As seen in the graph below from S&P Global, there is also a decrease in the U.S. manufacturing purchasing managers index (PMI). A report from S&P Global states that the PMI has fallen from 57% in June of 2020 to 54% in June of 2022.

The purchasing managers index can be used to make inferences about U.S. economic activity and offer predictions for the future. The purchasing managers index is obtained by compiling the survey answers of many business managers in their sector into one number from 0% to 100%. A PMI of 50% means no change, a PMI of less than 50% implies deterioration, and a PMI of greater than 50% means improvement.

Based on the data from each figure above, not every recession is the same, but there is one common denominator: inflated costs and a shift in manufacturing. Due to inflated costs of supplies, labor, and production, there is a likelihood that some manufacturers may lose their business during a recession because of smaller and smaller profit margins.

So, how can manufacturers alleviate some of these issues? The answer may lie in 3D printing.

3D Printing Offers Relief from Recession-Borne Challenges

At a glance:

- Parts can be locally printed to dramatically decrease wait time

- 3D printing can print any part imaginable with almost any material

- Fewer production cycles, materials used, and less time spent throughout production keeps costs incredibly low

- If the part you need is very old, then some manufacturers may not have the tooling necessary to create that part for you; 3D printing solves this

- If you know the exact part you need to print, a 3D printing provider can print it for you without giving an expensive custom order to a manufacturer with a long lead time.

Many of the problems in today’s manufacturing industry come from the recent COVID recession, such as supply chain delays, inventory storage, and labor shortages, can be solved with 3D printing.

3D printing nowadays has the capability to print almost any part or prototype imaginable with a variety of materials including plastics, resin, and powders. This creates flexibility in prototype designs and allows you to test multiple materials in minimal iterations.

With the use of 3D printing and knowing how long it takes to print something, manufacturers can have a component made and ready to ship whenever the next shipping vehicle arrives. This can lead to manufacturers being less reliant on inventory storage, as well as manufacturers being able to adjust to supply chain disruptions in the future.

3D printing also provides a significant benefit of producing complex components with less time. If manufacturers take this into account, it can lead to a reduced amount of labor needed to produce a single prototype.

Upload your models and get an instant FREE quote for your project, or contact us to discuss how 3D printing can help you create a low-cost, quick prototype.