A Solution To Spare Parts. Will 3D Printing Eliminate The Warehouse?

Is 3D Printing Spare Parts On Demand A Realistic Business Model?

Spare parts inventory can represent a significant portion of a company’s balance sheet but it’s something that nobody wants. Spare parts are held as insurance, whether that’s against downtime for components on your production line or to provide ongoing support to your customers. Managing this inventory is challenging, ensuring that you have just the right amount of stock available when you need it.

3D printing has long been hailed as the holy grail of spare parts management. The idea is that you no longer need to hold physical stock of your spare parts; instead, you store a digital file and when you have demand you simply print it – a true just-in-time manufacturing system. In this paper, we look at why 3D Printing can be used to meet the spare parts needs of organizations, where the challenges are today, and where businesses can seize short and long-term opportunities.

- What if you could print out spare parts as you need them, in a factory?

- What if your customers could print out spare parts at home using data that you have sent them?

- What if your distributors could print spare parts using online services?

- What if your customers began designing and printing their own spare parts?

WHAT IS 3D PRINTING OF SPARE PARTS?

3D Printing is a broad term, encompassing a wide range of technologies of varying maturity and capability. The 3D printers that are available today range from sub-$1000 for use within the home to multi-million dollar machines for industrial applications. A wide range of materials can be processed using this technology, including metals, plastics, and ceramics, although different materials often require different machines.

When thinking about 3D printing of spare parts, there are a number of different scenarios that we can consider:

Organizations 3D printing in factories

Where organizations are using high-end 3D printers within a production environment to meet the demand for spare parts, sourcing digital files from a catalog. This may include Original Equipment Manufacturers (OEMs) printing spare parts within their own factories, or outsourcing production to external suppliers with industrial 3D printing facilities.

Consumers 3D printing at home

Where consumers are printing spare parts for their products using low-end 3D printers in a domestic environment. The consumers may have designed the parts themselves or downloaded them from an online repository such as Thingiverse.

Online 3D printing service bureaus

Where organizations and consumers use high-end 3D printers within third-party service bureaus to print spare parts. Designers upload their designs to service bureaus such as Shapeways enabling consumers to purchase designs that are printed on demand by the service bureau.

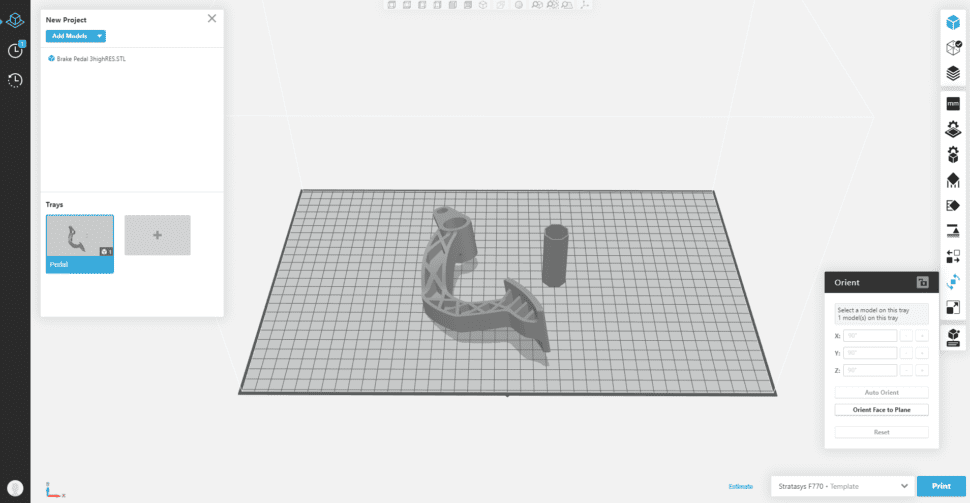

Within each of these scenarios, the workflow remains the same. Once the demand for a spare part has been raised, a digital model of the part must be obtained. This can be done by designing the component within a Computer Aided Design (CAD) package, scanning an original component, or – where possible – downloading an existing file from the internet. The digital model must then be prepared to make it suitable for printing – this process includes converting it to a suitable file format such as an STL or 3MF. The file is then transferred to a 3D printer for production. Following the print process, the component often requires post-processing to improve the aesthetics of mechanical properties – this may include heat treatment to relieve residual stresses or polishing to improve the surface finish. The component can then be delivered to the customer and installed as required.

WHY IS 3D PRINTING OF SPARE PARTS OF INTEREST TO SO MANY PEOPLE?

3D Printing can offer a number of benefits for companies looking to use the technology to support their spare parts and aftermarket service offer.

Reduced Inventory Costs

When it comes to spare parts, organizations inevitably face the challenge of balancing both lean and agile operations - attempting to simultaneously reduce costs while remaining responsive and flexible to meet customer demand. This situation necessitates a trade-off between the investment of holding a high number of spare parts as inventory and the ability to meet the demand of the customer on time. The ideal solution would be if organizations could instantly manufacture a product when the customer needs it. With traditional manufacturing processes, this is almost impossible as these processes usually have economies of scale – you need to make a high number of products to justify the cost of the tooling. However, economies of scale do not apply to 3D printing processes. In general, whether you are producing one component or 10,000 components, the cost per part is the same. This makes it a viable proposition for making one-off components, such as spare parts on demand.

Eliminating Component Obsolescence

From defense to aerospace, consumer products to telecoms, component obsolescence can be a major problem for organizations looking to support products over an extended period. This can be a particular problem for custom products and systems that are manufactured in low volumes or designed with a finite life. With an unlimited digital catalog of 3D printable files, component obsolescence is no longer an issue. Large quantities of stock or tooling do not need to be held indefinitely to support aged equipment.

New Routes To Customer Engagement

Sourcing replacement parts for a damaged or broken product can be an expensive and frustrating experience. 3D printing has the potential to improve the customer experience, by making it quicker, easier and cheaper to obtain spare parts. 3D Printing can enable new business models in which the customer can download digital data for their replacement part that has been verified by the OEM that they can print at home or online using a service bureau.

WHY IS THIS BEING USED TODAY?

Although 3D printing is often perceived to be a new technology, it has been in use for almost thirty years; as such it has found a wide range of applications to date, including the production of spare parts. A selection of examples are presented below:

Premium Baby Strollers

With a premium baby stroller costing in excess of $1,500, customers are understandably frustrated when spare parts are unavailable or disproportionately expensive. To serve this market, an entrepreneur has opened an online store selling spare parts for premium baby strollers through the online service bureau, Shapeways. The entrepreneur uses reverse engineering to create digital files of stroller components that he believes are likely to fail. These designs are then uploaded to the Shapeways platform, through which customers are able to order components. The components are produced on demand by Shapeways using high-end 3D printers in either metal or plastic and then shipped directly to the customer – anywhere in the world – for a fraction of the cost of purchasing it from the original equipment manufacturer.

Flat-Pack Furniture

Beloved by college students and first-time home buyers, flat-pack furniture has gained a worldwide reputation for being low-cost and functional. However, if you are unfortunate enough to lose the small pieces that hold it together, the furniture is essentially useless. To solve this problem, an entire catalog of printable components has been developed on file-sharing websites such as Thingiverse.com, where the file can be downloaded and printed at home for free using low-end 3D printers. These components are designed by hobbyists who use Creative Commons licensing to make the files freely available online.

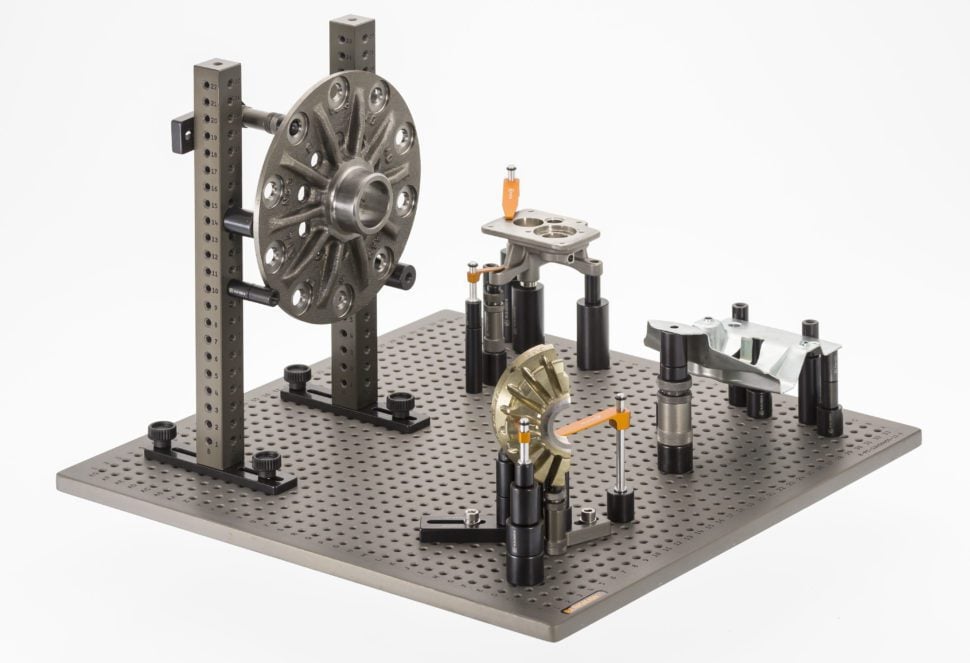

Spare Components for Production Lines

Maintaining production up-time is a critical factor for most manufacturing organizations. Equipment failure can have wide-ranging implications for everyone, from small enterprises to large corporations, affecting downstream processes and causing loss of revenue. 3D printing is increasingly being used to support manufacturing facilities and ensure that they are able to resume production as quickly as possible by providing replacement components on demand. In some instances, the replacement component may not be in the right material or meet the quality requirements but it is sufficient as a temporary measure until a permanent replacement can be sourced. A good case study of this application is from a Stratasys customer who used their 3D printer to replace a cracked aluminum pulley on a belt sander. The 3-year-old table-top sander was being used to remove burrs from steel parts in the finishing step of production items and the broken pulley had stopped production.

Automotive Aftermarket

There are an increasing number of examples of 3D printing being used to support the automotive aftermarket industry, especially in the classic car sector. The technology is being used to maintain vehicles where there is no manufacturing data available and the component is obsolete. A wide range of 3D printed spare parts for Classic Cars has been demonstrated, from printing small components such as door handles to enabling the production of replacement engine blocks. At present we are not aware of any major automotive OEM using additive manufacturing to support their aftermarket supply chains for current vehicles, but this is a key area of research for many organizations.

WHAT ARE THE CURRENT CHALLENGES TO PRINTING SPARE PARTS?

Despite the many benefits of using 3D printing to produce spare parts, adoption is still limited due to a number of challenges that the technology presents.

One of the biggest barriers to the adoption of 3D printing for spare parts is the issue of obtaining digital design data. Historically, very few products have been designed for 3D printing – they have been designed for manufacturing processes like injection molding, CNC machining, or casting. As such, there may be no original digital data available and so the component must be reverse-engineered and redesigned using CAD software, which can be a time-consuming task requiring skilled labor.

An alternative method of generating a digital model is 3D scanning, but this process is not without its challenges. It is rarely possible to scan a component and instantaneously generate a file that is suitable for printing. Instead, the user must repair the file which can be a difficult task. Additionally, most scanning technologies work on a “line-of-sight” basis, which means that very few are capable of capturing a component’s internal features – they can only capture the external profile of the component.

Limitations of the materials that are available for printing are a significant barrier to the adoption of the technology. Although 3D printing machines can process a wide range of materials, there are still many materials that cannot be printed or that have reduced mechanical properties when they are printed. Additionally, most printers can only process one material at a time, and there are only a limited number of components within a spare parts catalog that are made from a single material.

Finally, although the primary driver for adopting 3D printing to support spare parts is to reduce the inventory costs and the lead-time for obtaining a component, this must still be considered on a case-by-case basis. 3D printing can be an expensive and slow method of production – it can take several days to print a metal product – and so the technology is not applicable for all scenarios. Typically 3D printing is most suitable where there are high-value components with a low-stock-turn or a need to support expensive equipment over a long product lifecycle.

HOW WILL THIS CHANGE THE FUTURE

Improved access to printable digital models will be a key enabler in the adoption of 3D printing technology to support spare parts and aftermarket services. CAD modeling is now ubiquitous within product design and engineering environments, meaning that digital files for spare part components are increasingly available. These libraries of digital components will enable manufacturers and consumers to produce spare parts much more quickly and accurately. As the adoption of the technology grows, engineers are also beginning to follow the principles of “Design for 3D Printing”, in which components are designed specifically to be manufactured using 3D printing technologies. Again, this will contribute to reduced lead times and costs for 3D printed spare parts.

In addition, 3D printing has rapidly developed over the last thirty years, with significant increases in machine productivity and quality. Based on past developments and current research activities around the world, it is anticipated that this trajectory of development will continue, improving the production economics of 3D printing. This will create viable business cases for using 3D printing to manufacture a wider range of spare parts.

WHAT SHOULD COMPANIES DO TO PREPARE FOR 3D PRINTING OF SPARE PARTS?

In the short term, organizations should evaluate their spare parts catalog to assess the suitability of products for 3D printing, and identify if there are immediate opportunities to use the technology. This assessment should consider the technical and economic feasibility of implementing 3D printing within the supply chain and should look at factors such as the components’ material, size, and function as well as the costs associated with storing the component as inventory. Through this analysis, a business case can be built for the adoption of the technology as a replacement for conventional spare marts management solutions.

In the long term, companies should consider how they can use 3D printing to a strategic advantage. 3D printing is disrupting supply chains across a wide range of industries; spare parts are just one aspect of this. To reap the benefits that this technology offers, companies must develop corporate strategies for its adoption across the entire organization. In this way, spare parts can be designed at the outset for manufacture using 3D printing with innovative business models to support the sale and distribution of these spare parts.

CADimensions can help you understand the disruption that this technology could have on your business and assist in developing strategies for your adoption of this technology.