ABS-CF10: Stratasys’s Latest Carbon Fiber Material

“ABS-CF10 unlocks the potential of carbon fiber-reinforced thermoplastic on the easy-to-use F123 printers by delivering stronger, stiffer, and lighter weight parts.”

Stratasys

Carbon Fiber Properties

ABS-CF10 is 15% stronger and over 50% stiffer than traditional ABS. Its key attributes are its high stiffness-to-weight ratio and low moisture sensitivity. It is accurate up to 0.2mm with layer resolutions of 7, 10, and 13 thousandths of an inch (0.178, 0.254, and 0.330 mm). This allows for excellent geometric tolerancing over large parts. As for the surface quality of the material, it depends highly on the geometry. It can be very nice in the Z direction, but rough in the XY direction due to the carbon fibers in the resin. This material excels at functional testing and use, not necessarily aesthetics. Produce parts that are reliable, accurate and repeatable with carbon fiber.

ABS-CF10 Compatibility

ABS-CF10 is available on the F170, F270, and F370 printers from Stratasys.

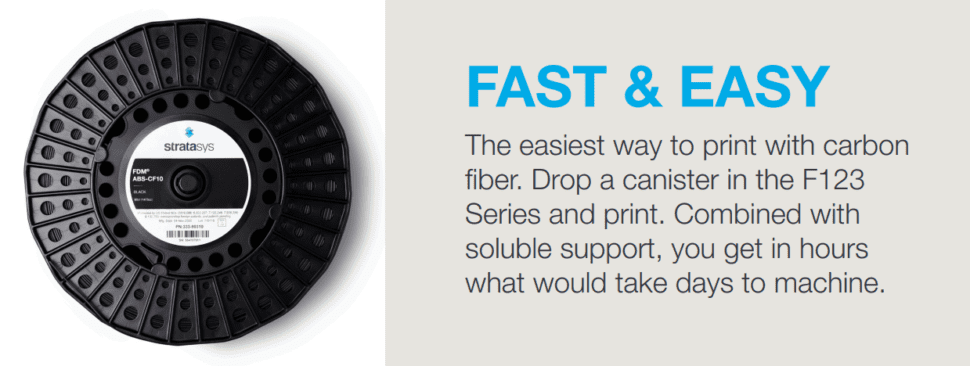

A print head upgrade is required due to the abrasive nature of the filament. This material head is dedicated for ABS-CF10 only. The print head is user changeable and has a lifetime of 700 hours. No other internal components besides the head will show signs of additional wear. Carbon fiber prints with QSR soluble support material on a standard build tray, just like traditional ABS. Using this material is the easiest way to print with carbon fiber. With the convenience of soluble support, you get in hours what would take days to machine.

ABS-CF10 Applications

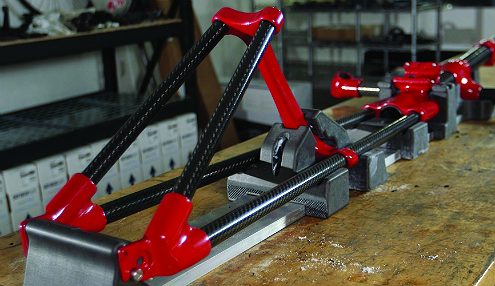

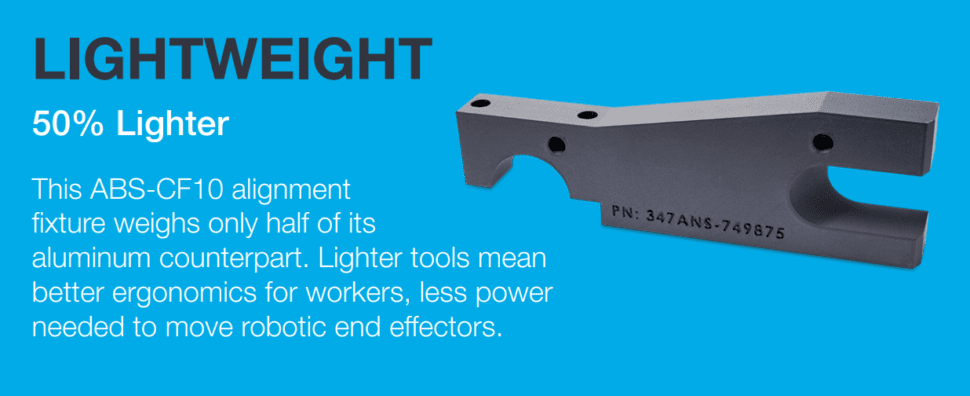

Manufacturing tooling can be heavy and expensive. With ABS-CF10 you can produce strong, light weight jigs and fixtures that will not deform or break the bank. This material is perfect for functional prototypes, tooling applications, and production parts. Alignment tools, end effectors, sheet metal forming, and ergonomic aids are all great applications of this new material. Parts printed with ABS-CF10 will have a shorter lead time and be more cost effective to produce than traditional manufacturing methods. Industries that would benefit from using an F123 Series printer with ABS-CF10 include aerospace and defense, transportation, automotive, consumer packaged goods, and general manufacturing.

Carbon fiber for the F123 Series is finally here! We are very excited for this newest addition to the Stratasys material family and we think you will be too. ABS-CF10 is available now so get started on printing strong, lightweight, and repeatable parts today.