CAD Simulation Explained. Everything You Need To Know.

You’re in charge of the product development team at your company. But before you hit the market with your latest product, it needs to be tested. That’s where CAD simulation comes in.

What is CAD Simulation?

CAD is the acronym for Computer-Aided Design. It essentially means you are using computer software (like SOLIDWORKS) to create a three-dimensional object that you can then test.

From a CAD perspective, simulations are basically virtual experiments. These virtual prototypes allow you to test physical components without having the physical product or part which makes CAD simulations extremely valuable because it saves both time and money in the design process.

To run a proper simulation, you must model the physical characteristics and the material properties of whatever object, product, or prototype you are working with to gain accurate results.

In the simulation, you can test different properties and factors like material properties, load magnitude, and load direction - almost to an infinite degree which is what makes it so powerful.

Types of CAD Simulations

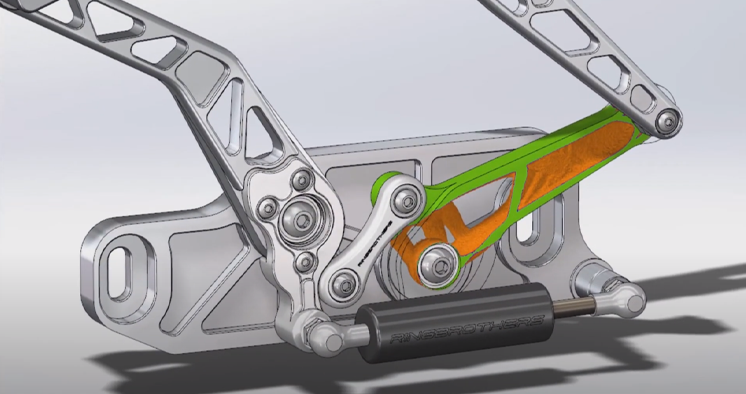

Simulation can be used for things like product optimization or stress testing an object. Each type of CAD simulation focuses on a unique situation that can produce quantitative or qualitative (visual data) results.

Structural Simulation/Stress Analysis

Decrease your product development cycle with a structural simulation. This type of CAD test will ensure your model won’t fail and can perform under the given loading conditions.

Flow Simulation

Flow simulations in CAD are optimal for improving fluid elements in your design. For example, you might need to reconfigure cooling elements or test pressure fluctuations.

Injection Molding Simulation

Injection molding simulations allow you to test whether the part geometry will fill correctly before you even cut the mold. You can also optimize injection locations, cooling line placement, and part warpage.

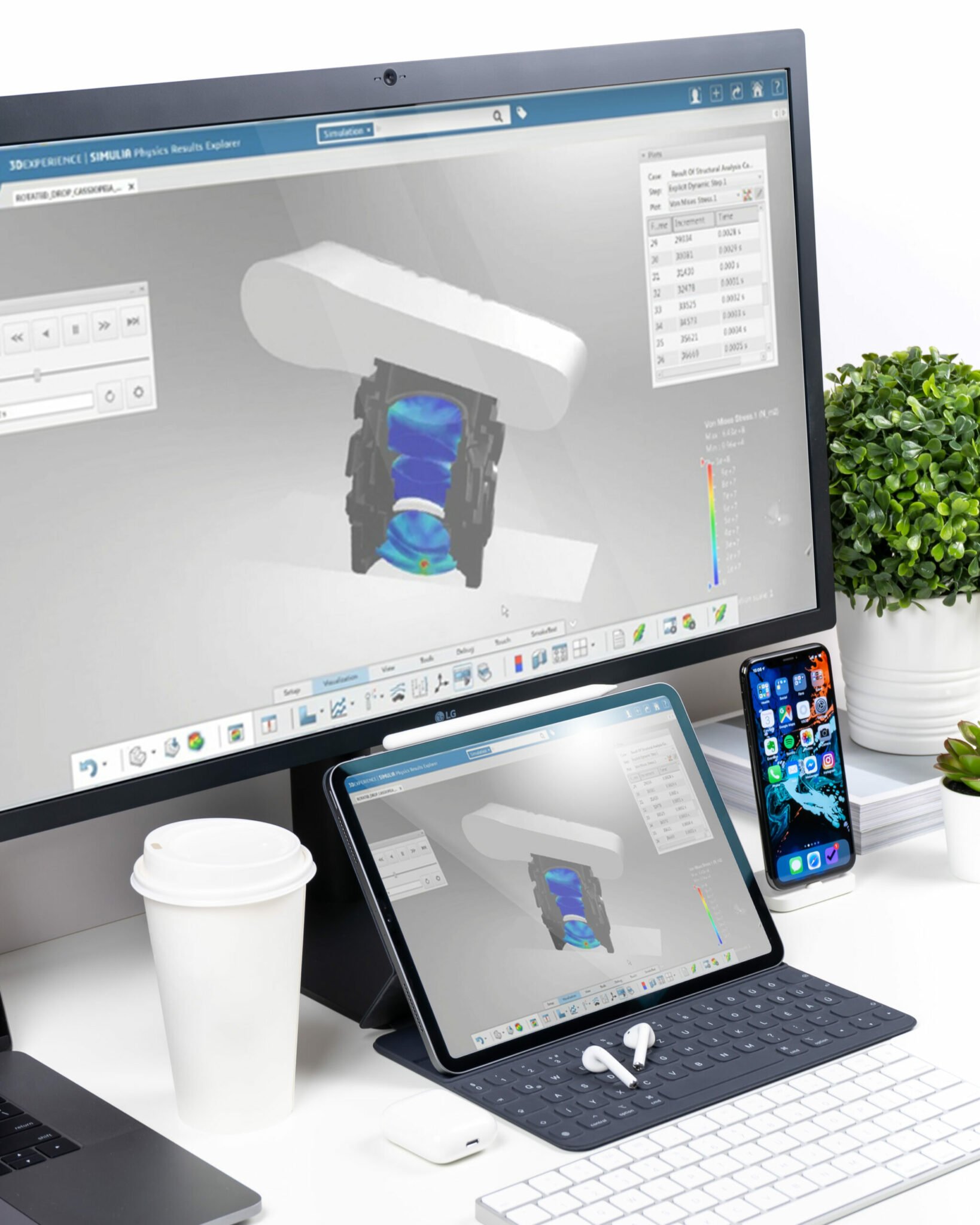

CAD Simulations Predict Real-World Situations

The best thing about CAD simulations is that they provide real-world data. A simulation can give insight into structural problems and failure points in your physical product. So, you can be more reactive to changes and foresee any issues early on.

Speaking of real-world data, we take your project, run simulations per your requirements, and then deliver a slew of information. You receive PDF reports, plots, charts, graphics, and the SOLIDWORKS files with the revised data.

Running a CAD simulation also helps you get to market faster because you can test all of your components and checkpoints without ever having to build a complete prototype. So, you can examine theoretical situations and gather as much data as needed without hard restrictions.

Getting Your Project Simulated

If you have a project that requires CAD simulation, you can either do it in-house or hire out the work. Hiring experts like CADimensions will end up saving your team an immense amount of resources.

Why? There comes a large time, money, and knowledge investment for simulation tools as well as engineers who are skilled in running simulation studies. By allowing CADimensions to be your partner in design and simulation projects, you’ll have reduced overhead costs and forego the need to hire new simulation engineers. CADimensions has over 20 years of experience in CAD simulations from a wide range of industries and we are here to assure your products hit the market seamlessly.

See what the CADimensions team can offer and the simulation services we can provide for you on your next project.