Does Online CAD Simulation Save Money?

My budget doesn’t allow for any molding rework. How can I be sure I get it right the first time?

Up-front costs of molds are pretty expensive, ranging from $10-100k. So, when there is an error, recreating a model is very resource-draining both in dollars and time. Too many companies overlook the value of using CAD data to perform simulations and save money.

Most budgets don’t account for having to pay for reworking or scraping the mold and starting over.

An astounding 80% of the cost of product development is determined by decisions made in the early stages of the design process. By testing your design upfront using online CAD simulation, you’ll be able to determine the strength and integrity of your product before you make the molds.

This will save both time and money in the long run because issues are found early on as opposed to when the model is finalized.

The Case of the Tacoma Narrows Bridge

Seventy-five years ago, the Tacoma Narrows Bridge made headlines when it swayed unlike people had ever seen.

A section of the bridge twisted so strongly it broke and fell, crumbling the bridge. “Galloping Gertie” joined many others in a cautionary tale of engineering gone wrong.

This situation is an extreme example of failing to test a design, but if proper testing isn’t done it absolutely has real-world consequences. Whether that’s a bad bridge or a bad battery, failure is likely when you create something in the real world without thorough testing.

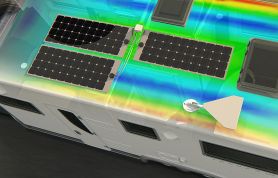

By simulating a prototype virtually, you can address the problems within the model before you even build it. Simulation can verify if your design will withstand the physical environment you’re putting it in.

Problem Solving Benefits of Online CAD Simulation

Simulation allows you to visually experiment with the model in new ways from an unrestrained perspective. Undergoing this experimental process increases design accuracy, enhances your existing design, and evaluates critical design parameters.

For example, you can freely experiment with your design’s aesthetics, hardware placements, features, and organization.

Additionally, weight equals money in terms of materials. CAD simulation maximizes performance and cost-efficiency through material selection.

You can quickly change materials within the simulation to determine which raw material will save you money and be more durable in a real-life use case.

Getting Your Project Simulated in SOLIDWORKS

If you have a project that requires online CAD simulation, you’re going to be faced with two options: do it in-house or hire out the work. In the long run, it will end up saving your team an immense amount of resources.

Why? Because you need not only the software but also the talent. You’ll have reduced overhead costs because you’re taking all that out of house for the occasional simulation projects you have.

You can get your project simulated in SOLIDWORKS or with the power of the 3DExperience platform by our team of engineers today, or if you’re unsure what exactly you need, someone will be happy to point you in the right direction.