How SMARTTECH3D Scanning Helps Mass Produce Art

New 3D technologies, like SMARTTECH3D scanning, are vital in many industries, departments, and fields all over the world. These technological advancements are popping up everywhere; our homes, at work, and even our commute. But, we’re not always aware of how important these innovations are in the creation of products that we use every day.

When drinking tea from a beautiful porcelain cup, we do not usually think about the long journey this product has gone through to reach our hands. Most people tend to imagine a single factory where the cup is cast, dried, painted and sold, all in the same place. Although that process is easier to wrap your head around, it’s rarely true.

The creation of products is very complicated. To beat the competition, creators need to have modern solutions for these intricate problems. One vital key to success is designing an original shape and pattern for the product. But how can you design something new when almost all possible patterns and colors are already on the market? One of the biggest tableware manufactures in Poland, Lubiana, stood before such a challenge. They have been in operation since 1969, distributing over 3.5 million porcelain products per month on a global scale. Lubiana can do it all, from one-of-a-kind promotional and individual orders all the way up to dedicated product lines. Their porcelain often stands out from its competition due to their beautifully unique designs.

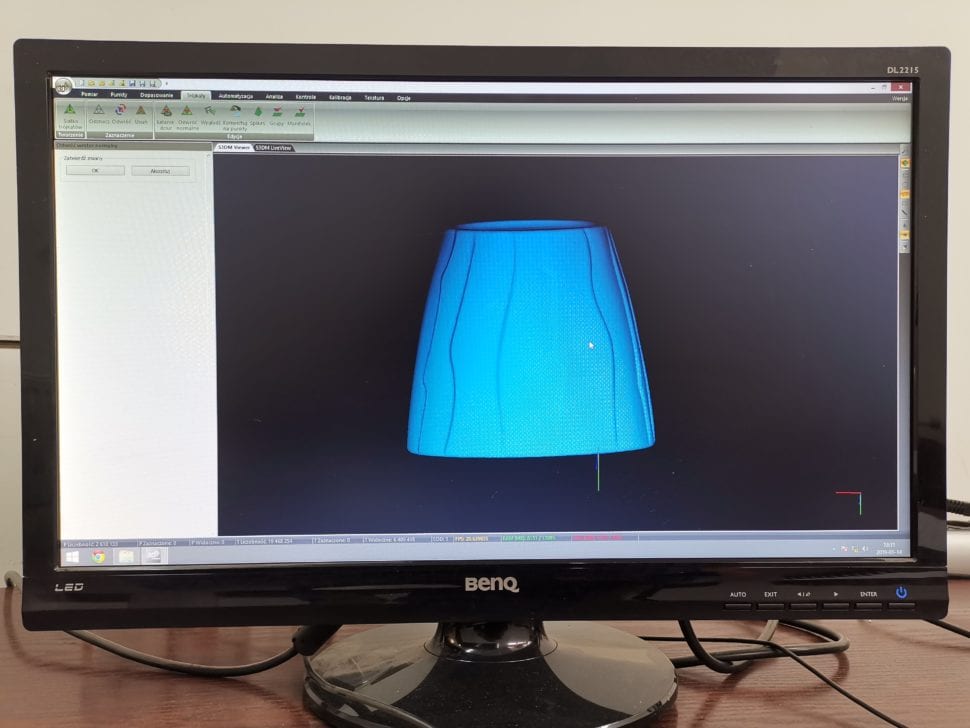

Let’s return to the cup that was referenced earlier. Lubiana commissions sculptors to create a product that is interesting and uniquely shaped. The artists sculpt and cast their work, which is a traditional method to make porcelain. The designs are often very detailed, have small parts, decorative reliefs, and shapes. Once complete, to prepare it for mass production, the artist sends the product to Lubiana. It is then 3D scanned with SMARTTECH3D and analyzed with SMARTTECH3D measure software.

Measurements that used to take days now takes only minutes. The scanner records the geometry and color information of the object by creating a point cloud. This point cloud contains millions of individual data points, each containing X, Y, and Z coordinates, as well as color information. SMARTTECH3D measure software takes this point cloud data and maps it into millions of triangles, creating a highly accurate digital replica of the object.

3D Scanning Damaged 3D Printed Parts IN SECONDS Instead of Hours

At a basic level, it is easy to look at a part and recognize that it has changed shape. Figuring out exactly how the part changed shape is a much bigger challenge. If you are an engineer, figuring out how the part changed shape at different levels of force could be a valuable tool in designing better parts.

After Lubiana has the triangular mesh of the product, a mold is then 3D printed or milled on a CNC. The unique design of the artist is thus reproduced on a large scale in an unchanged format and is ready for the consumer. This is how a beautiful porcelain cup goes into our hands and accompanies us in everyday activities. Although it isn’t as simple as previously imagined, SMARTTECH3D has made a proven solution to easily recreate intricate designs that are ready for mass production.

The company Lubiana has been using 3D scanning technology from SMARTTECH since 2014; however, in 2019, it decided to upgrade the SMARTTECH3Dmeasure software to the latest version of v.2019 and recalibrate the previously purchased 3D scanner from SMARTTECH. As pointed out by Zbigniew Andrzejewski, General Director of Lubiana, “We received the software that is characterized by a high standard and modern technology with efficient parameters and functions and a significant increase in productivity over the models. We are satisfied with the decision to buy the equipment upgrade.”