PA12: The New Material for the Stratasys H350

When Stratasys launched the H350 3D printer last year, it was compatible with one single material, PA11. They are now ready to release the most requested polymer in the powder-bed printing space: PA12. Stratasys SAF PA12 delivers production-grade plastic parts for high-volume demands. It enables a high nesting density while maintaining high part consistency to deliver production-level yields.

The Original H350 Material

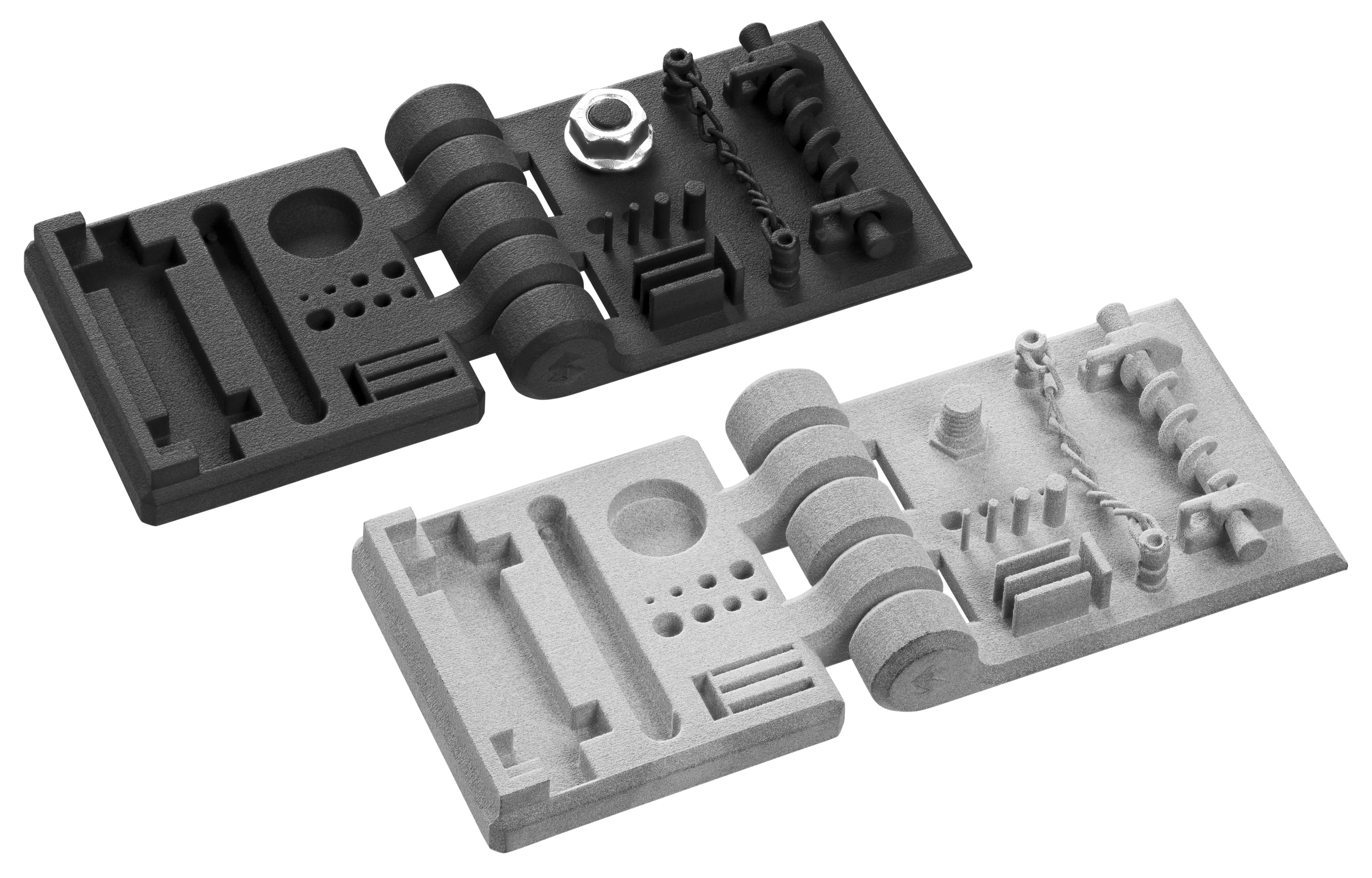

At the time of its release, the H350 was printed in one single material: PA11. This is a nylon powder made from 100% renewable castor beans. It offers high ductility, excellent impact strength, and fatigue resistance, all with a quality surface finish and low environmental impact.

You may be wondering why Stratasys would release PA12, the more widely used material, after PA11. There were a few factors that went into this decision. First, PA11 is historically seen as a difficult material to process. Stratasys wanted to dial in the more difficult material first. Second, PA11 has a strong environmental message for those focusing on sustainability. And lastly, PA11 has a higher melting temperature, so if they build the hardware to process PA11 first, the latter would be no issue.

PA12 is a highly versatile nylon polymer for a wide range of popular applications. Its mechanical properties vary slightly from PA11, and while their applications certainly have overlap, PA12 has advantages of its own. Regardless, both materials benefit from being processed with SAF™ technology on the Stratasys H350™ 3D printer.

PA12 Benefits

Combining the consistency of the H350 platform, SAF PA12 delivers repeatable mechanical, aesthetic, and accuracy properties throughout the build volume. It elevates the additive manufacturing capabilities of powder-bed printing. Category-leading accuracy takes complex geometries to new heights of precision while ensuring that parts are nested efficiently, lowering the cost of parts across the board.

Compared to PA11:

- Cheaper per Kg

- More accurate

- Stiffer

- Less ductile

- Less prone to warp

PA12 Key Use Cases

The list of use cases for PA12 is endless, but there are a few key sectors that are using this material the most: automotive, industrial machinery components, and consumer goods.

Within the automotive and transportation industry, PA12 and the H350 printer can be used to produce a broad range of interior parts such as electrical cable clips and connectors, air ducts, sensor brackets, side mirrors and more. Highly regulated industries like automotive require part- and material-specific certification. With the H350, you can certify the products and parameters for your customers, log build data and receive process traceability.

Industrial machinery components are also a great fit for PA12 and SAF technology. Brackets, bearing and gearbox components, close fits, and couplings are all possible with tighter achievable tolerances.

For the consumer goods industry, applications not requiring high-impact resistance are more suitable for PA12 than PA11, but there is an immense opportunity to leverage the agility of 3D printing to produce end-use parts that consumers use every day. On this note, I am an avid golfer, and my irons have a PA12 powder-bed fusion part on their backing. I expect to see more powder-bed parts, especially PA12, find their way into consumers’ hands with new exciting and innovative products.

Why You Should Consider PA12

SAF PA12 is the most accurate, cost-effective polymer, increasing manufacturing possibilities across a range of sectors whilst lowering the cost of parts. Combined with the H350™ 3D printer powered by SAF™ technology, SAF™PA12 produces robust production-grade parts that meet the demands of modern industry.

PA12 represents the latest step from Stratasys to empower manufacturers. This material will make additive manufacturing of volume part production more flexible and agile, with all the control, consistency, and performance you’ve come to expect from the leading powder-bed printing platform. Stratasys is uniquely positioned as the global leader in 3D printing, and their H350 3D printer paired with PA12 material is pushing the additive industry past just prototyping and into full-fledged production.