SLA vs. PolyJet: What You Need to Know

Today we’re trying to answer a very important question that many people looking to get into 3D printing, or expand their 3D printing capabilities ask themselves: What 3D printer should I buy? Or in my experience, engineers and project managers are usually really looking for the answer to deeper questions: What 3D Printing technology is right for me? What 3D Printing technology will get our desired results?

Let’s compare SLA and PolyJet 3D printing methods, which are usually the best options for users who want creating beautiful, smooth models, or for anyone who wants to 3D print transparent or translucent components.

What is SLA

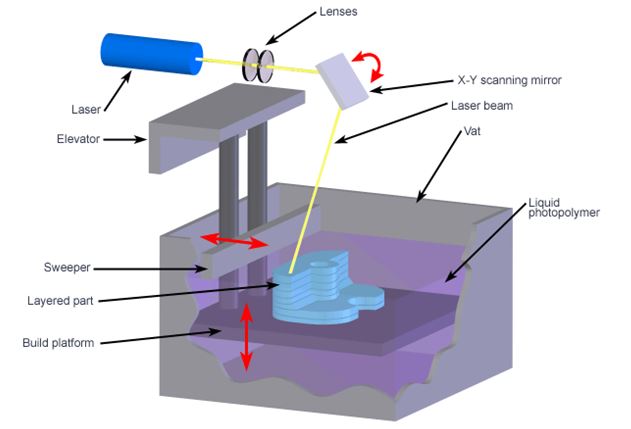

The oldest 3D printing technology is SLA, an abbreviation for stereolithography. Typically, 3D printers that use this method use a liquid resin that becomes solid when exposed to the light from a UV laser.

The laser is controlled using motors and mirrors to trace out the cross sections of objects in layers. These layers stack on top of one another to create the desired object. In its most common configuration, objects are built upside-down, as the build plate moves up and “pulls” the object out of a pool of resin.

The Benefits and Drawbacks to SLA

SLA 3D printing has a handful of pros and cons. SLA models usually look beautiful. Because SLA 3D printers start with a liquid, they’re able to print in very small layer heights that decrease or eliminate the layer lines that are an immediate indicator that an object was 3D printed.

Many users find that SLA parts are fragile, despite material science making vast improvements in part strength since the technology’s discovery in the early

SLA printing can be messy. The open pool of resin can have a strong chemical smell, and parts that come off the build tray will have liquid resin residue on them, and typically need a two-stage alcohol washing process to make them safe for handling. The resin used is a skin and eye irritant, and some have been known to cause cancer, so gloves are a must when handling parts before washing. Large SLA parts often need to be post-cured in a chamber full of UV light in order to gain their full strength.

Why PolyJet is Different

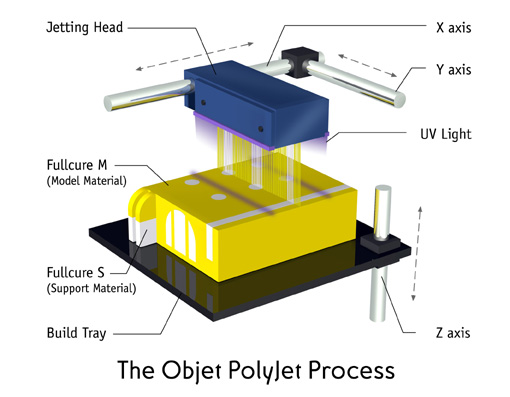

PolyJet 3D printers use a UV-cured liquid resin just like SLA 3D printers, however, the similarities start and end there. PolyJet 3D printers use an inkjet-like print head to distribute the resin onto the print bed, eliminating the need for the messy, smelly, and hazardous pool of resin used in SLA machines.

This method of printing offers a lot of advantages over SLA 3D printing. SLA 3D printers only use one material at a time, making them only capable of using break-away support material. PolyJet printers use a wash-away or soluble gel-like support material, making them capable of very complicated geometries and assemblies of parts that print together.

PolyJet parts come off the build platform fully-cured without any liquid resin residue, eliminating the need for multiple alcohol baths to wash the

PolyJet’s Biggest Advantage

Perhaps the biggest advantage of PolyJet 3D printing is its multi-material capability. Connex 3D printers can blend soft rubber-like materials with a rigid material to create different levels or rigidity or softness in various components of a single print job, allowing for unparalleled prototyping capabilities compared to any other 3D printing process.

This resin-mixing capability opens the door to create strong Digital Materials for more robust, yet smooth prototypes. At the highest level, the J750 can blend up to six resins together to create full color and full gradient models, defining their properties pixel-by-pixel in 3D.

PolyJet Takes SLA Printing to a New Level

Both SLA and PolyJet have an important place in the 3D printing ecosystem. SLA creates beautiful, detailed models, but is limited by breakaway support material, and overall mess created by the process. PolyJet technology takes resin-based 3D printing to a new level, with soluble support material, better print speed, and unmatched multi-material capabilities.

While users looking to create simple models and materials with a smooth surface finish may find a great solution with an SLA 3D printer, those looking PolyJet’s added benefits will not find it anywhere else.