Stratasys Origin One: A 3D Printer for Production Parts

In December of 2020, Stratasys acquired the UK based 3D printing company Origin. This Spring, Stratasys announces the first machine to come out of this acquisition: The Stratasys Origin® One.

Thanks to the systems proprietary Programable PhotoPolymerization (or P3™) technology, the Stratasys Origin® One is able to manufacture production-quality end-use parts from a wide variety of high performance materials. The system also delivers industry leading accuracy, repeatability and time to part capabilities. With production-quality end-use parts as the point of focus for this machine, the Stratasys Origin One is capable of producing parts with surface finishes that rival injection molding.

Elaborating on Origin’s first printer, the Origin One, Stratasys decided to enlarge the working build volume and add a number of hardware and software upgrades. These upgrades improved ease of use, serviceability, performance, and throughput. Future software updates will also be available to the install base via cloud delivered updates to ensure the machine is always running the most up to date firmware.

Launching with 10 fully certified materials from chemical company partners such as Henkel, BASF, and DSM, the Origin One is an ecosystem that allows you to not only utilize the certified materials, but also develop new materials for your specific application. Between the 10 certified materials available at launch and the option for customers to develop more, the applications for the Origin One are endless.

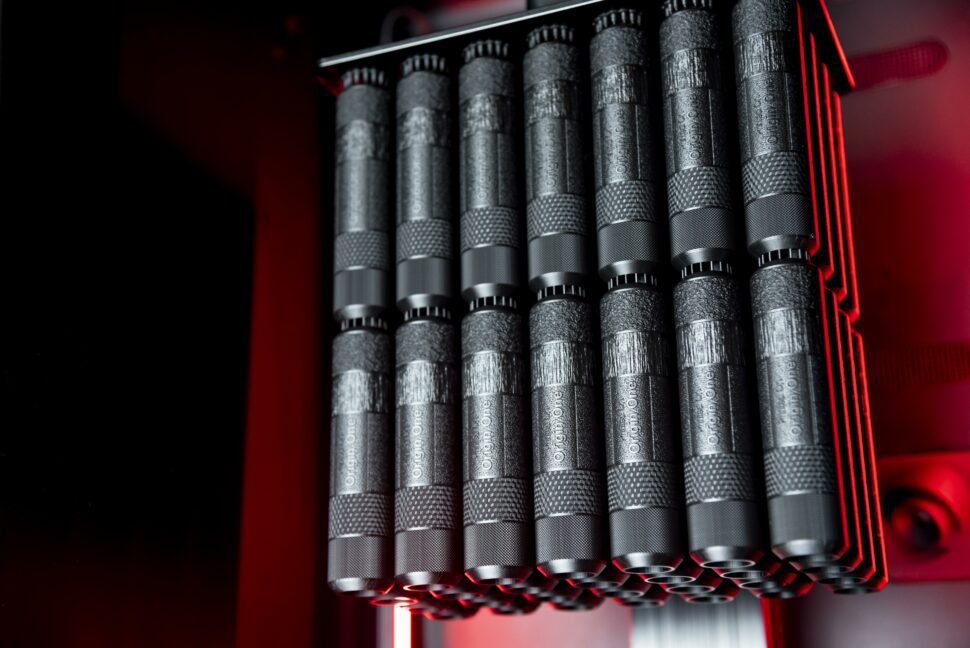

TE Connectivity, a world leader in connectors and sensors, was one of Origin’s first customers and owns several machines. TE has collaborated with Origin and Henkel on an aerospace-grade photopolymer that has passed rigorous industry-required environmental tests. Today, TE is producing thousands of parts, including its first-ever 3D-printed aerospace production product; the 369 Series connector holder is designed to help connectors inside of airplanes remain mated.

“We have been laser-focused on meeting stringent accuracy and repeatability criteria for connectors that require double-digit micron accuracy. Stratasys and Origin have been great partners in helping us achieve these targets and demonstrating the possibilities of using additive manufacturing at the scale of tens of thousands of parts. We believe this helps make TE Connectivity a more agile and cost-effective partner for many of the world’s leading OEMs in industries from automotive to aerospace to appliances as we work to build a more connected future.” -Mark Savage, Global Center of Excellence Leader and Senior Manager of Additive Manufacturing at TE Connectivity

The Stratasys Origin One has a build volume of 7.55” x 4.25” x 14.57” and can print detailed features down to 50 microns in size. The 10 fully certified materials include high temperature, tough, elastomer, general purpose, and medical grade material options. If you would like to learn more about the system, register for our upcoming webinar below.