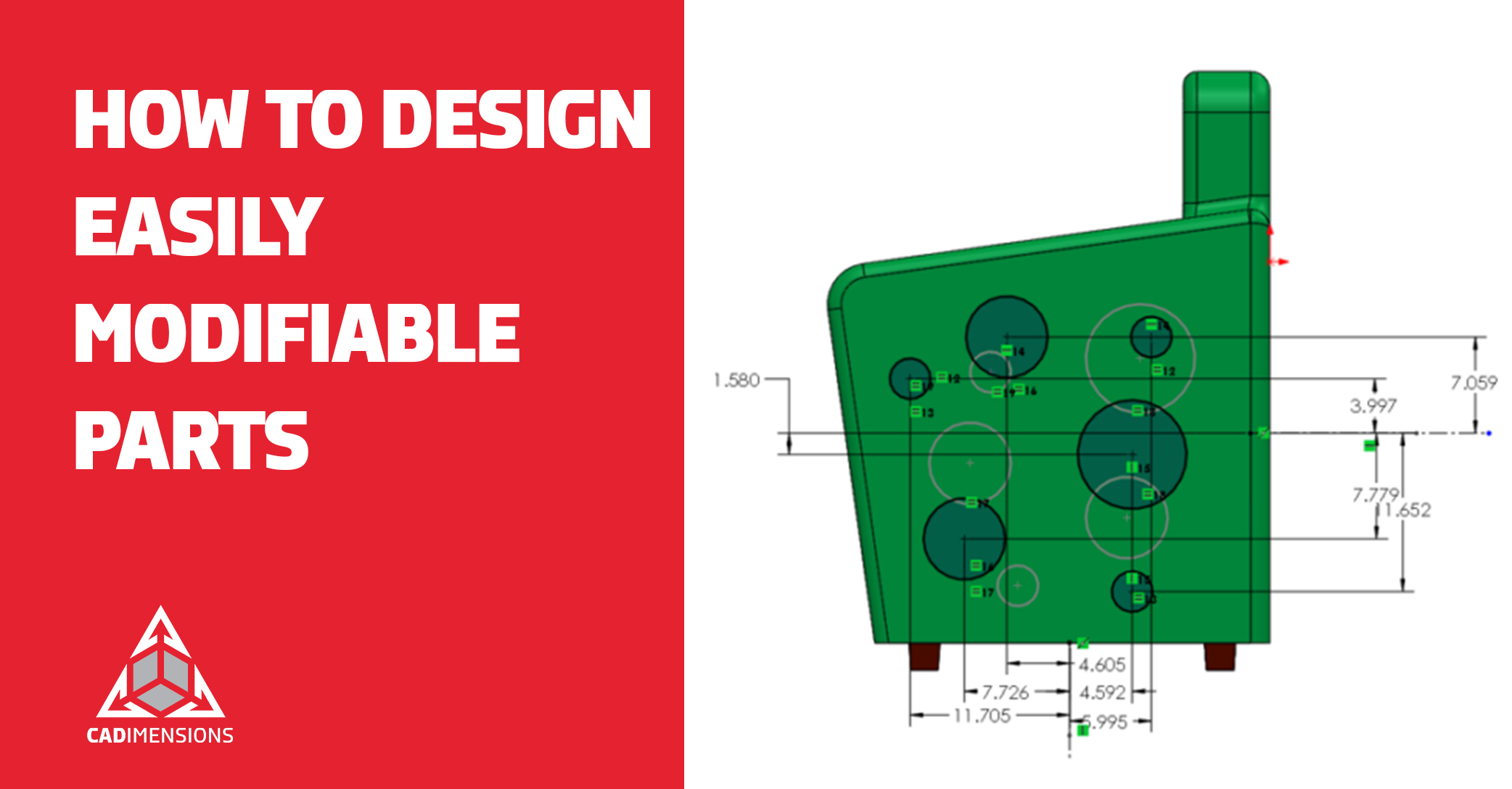

Tips to Designing Parts to be Easily Modifiable

Designing a product is not always a straightforward process. There are usually several iterations of a product, especially during the research and development phase. Maybe there are manufacturing requirements that change, or ergonomic improvements. These changes can wreak havoc on your SOLIDWORKS models, but there are some tricks and tips to make this a smoother process.

Design Intent

Design Intent is the method and process where the user/designer decides what is important in the model and anticipates how it may change in the future. By considering the design intent, you can set up the model with appropriate planes and relationships, so that the model is robust enough to accept these future modifications. Take some time when setting up your part. For instance, if you have a part with symmetry, have a center plane so that you can model one half, and simply mirror the other side. It is easier to modify a part that is built on a good foundation.

Relations & End Conditions

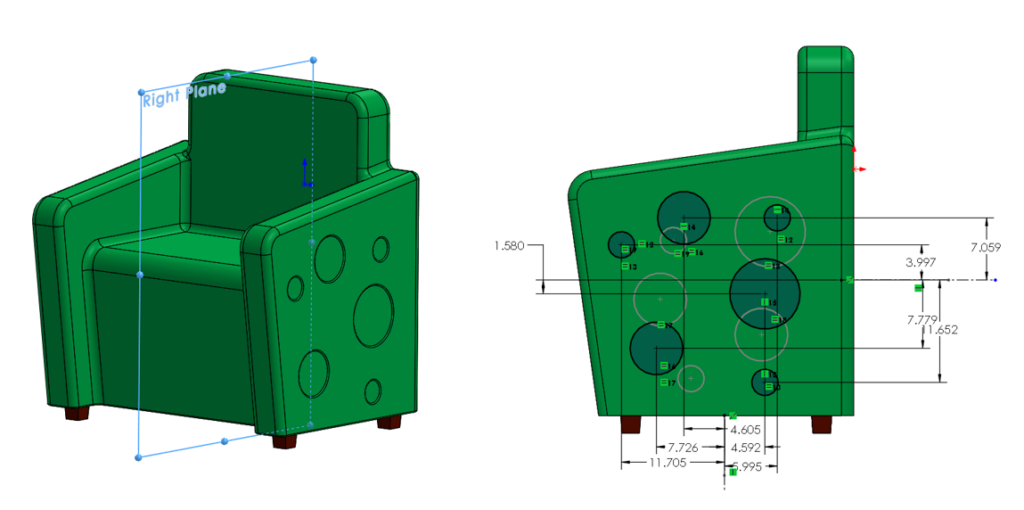

A large factor in having good design intent is utilizing relations and end conditions. Relations are how entities in your sketches and features are related to each other. If you have multiple sketches that you know have commonalities, you can even relate to entities outside of a sketch. For instance, on this chair we have here, there is a circular pattern sketch on multiple sides. By setting up relations, all sketches are linked, so that if you update one, the others update as well.

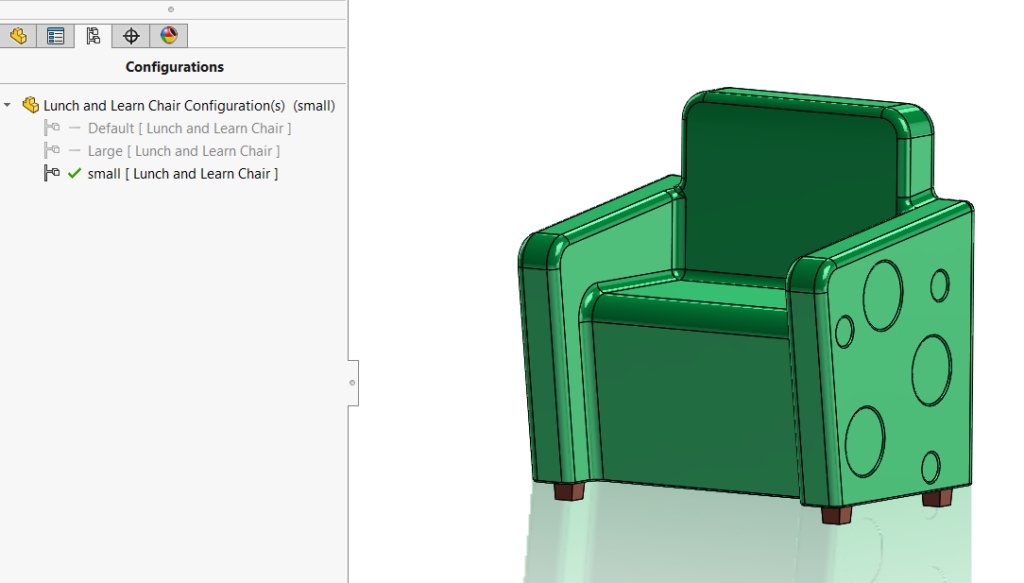

Configurations

Are you designing multiple parts that are very similar, with some minor differences? Or maybe you want to compare some design options, that have certain features included or missing. Configurations might help! Configurations allow you to represent multiple versions of a part in the same file. You can suppress specific features, change specific dimensions, and even link display states in configurations. Every part starts with a single configuration, and you can manage these on the Configuration Manager. For instance, this chair has a small and large versions. By configuring specific dimensions, you can view both versions in the same file.

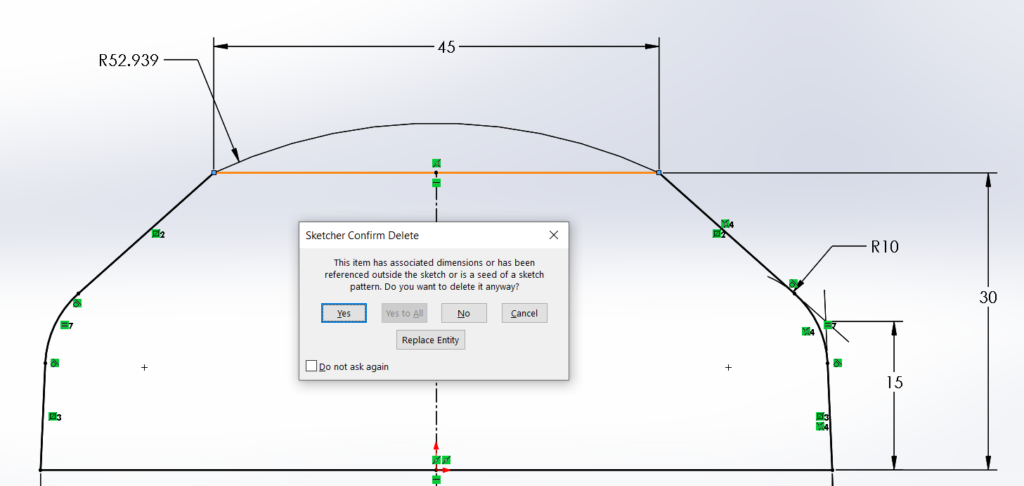

The Replace Entity Tool

One of my favorite tools that you might not be aware of is the Replace Entity Tool. Let’s say you are designing a product and get some customer feedback on a needed change that affects a feature/sketch high up in your feature tree. As you might know since SOLIDWORKS is history based. So if you make a change early in the tree, this can affect features downstream that reference it. By using this tool when modifying a sketch, it can automatically update those references, reducing the need to go in and fix broken references manually. This can be a lifesaver, especially if you need to make modifications that greatly affect other aspects of your model. To use this function, when you delete a sketch entity that has references, you will be prompted with a window called “Sketcher Confirm Delete.” Use the “Replace Entity” option to reattach the associated dimensions.

Conclusion

Whether you’re designing a simple or complex part, some things like design intent hold true for all projects. This makes it easier on you, and your co-workers, by building your part to handle potential changes down the road. If you would like to learn more, check out CADimension’s training classes found here. Or, if you and/or your company need an extra hand, we also offer design services to help you get a better product to market quickly and efficiently. Check out the services we offer on our website. We are happy to help and assist you on your innovation journey!