Top 3 Uses For Carbon Fiber 3D Printing In Manufacturing

Carbon Fiber 3D Printing is a growing division of the Additive Manufacturing world. As this material is growing in popularity, it has become apparent that Carbon Fiber 3D Printing has enhanced qualities and increased versatility that make it preferred in some manufacturing contexts.

What is Carbon Fiber and What are its Advantages?

Carbon Fiber 3D Printing uses a composite material consisting of polymer mixed with chopped carbon fiber. The combination of these two materials results in a unique printing medium that rivals traditionally manufactured aluminum parts in some applications. Carbon Fiber printed parts are light and durable which allows them to be more desirable for prototyping in that they stand up to clients’ expectations of strength while outperforming heavier materials in weight. Finished Carbon Fiber 3D printed parts maintain such a high stiffness-to-weight ratio that they have the potential to replace aluminum parts without sacrificing strength in certain manufacturing situations. Here are the Top 3 Use Cases where we see customers leveraging this material.

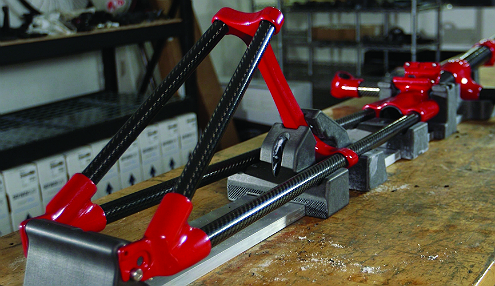

Tooling Optimization

Along with the performance benefits of lighter parts printed from Carbon Fiber material, the unique properties of additive manufacturing leaves designers with fewer design constraints. This allows designers to optimize parts for operator comfort and longevity by being more ergonomically effective. By making parts lighter and more comfortable, designers are able to reduce strain on assemblers and others involved in the manufacturing process. Carbon Fiber 3D printing allows for lighter parts and more organic shapes as compared to traditional manufacturing which is especially beneficial for 3D printed jigs and fixtures that operators are required to interact with. Optimal ergonomic designs for operator use can be realized by utilizing the benefits of Carbon Fiber printing without sacrificing strength.

Functional Prototyping

Carbon Fiber 3D printing can be used to create prototypes that not only prove the designer’s concept but also allow the designer to functionally test their part with real-life strain and mobility. The high strength and durability of Carbon Fiber give this material the structural rigor that is necessary to withstand real-world testing. This feature of Carbon Fiber printing adds to the versatility of this manufacturing process as multiple iterations of products are often required in order to finalize a design. The time-efficient benefits of Carbon Fiber printing are further demonstrated as prototype testing can be attempted as soon as the print has been completed.

Carbon Fiber 3D Printing For End-Use Parts

Taking the functionality of Carbon Fiber printing one step further, some companies have been able to utilize the performance benefits of Carbon Fiber to adapt end-use parts. Utah Trikes, for example, was able to utilize the high strength-to-weight ratio of Carbon Fiber 3D prints to manufacture end-use parts on their custom bikes and tricycles. “The FDM Nylon 12CF is fantastic. It’s changing everything for us,” CEO Ashley Guy said. He cites the strength of the material, as well as its soluble support as game-changers. Additionally, “We can take the part and put it into our tumbler overnight and it comes out with a smooth, polished finish,” said Guy. “Let’s face it, when it came down to bolting a part on a trike and heading down a hill on it, it was only the Stratasys FDM Nylon 12CF that held up.” As an added benefit, the ability to bring production of these parts in-house allowed Utah Trikes to cut the lead time down from 2 months to 2 weeks.

It is exciting to see the advancement in materials with 3D Printing like what Carbon Fiber brings to the table. This really opens up the door to what customers and users are going to be able to do with this great technology.