Why Additive Manufacturing is Critical to OEM Success

OEMs and Modern Manufacturing

You can add the label OEM or ‘industrial equipment machinery’ to everything from pick n’ place robotics, to heavy mining machinery but regardless of the output, the companies making this equipment face similar challenges. Additive Manufacturing is just one part of the solution.

Customization

When it comes to the production of industrial equipment, one size most certainly won’t fit all. A huge majority of machines are built to exact specifications, unique to their application and purpose. These requirements are usually determined by the customer and have very little margin for error. As consumer demand for more customization has grown, so too has the need to produce with more flexibility and that is a burden shared with the OEM.

Your customers are looking for equipment that will do exactly what they need it to do, day in and day out. When their requirements change, they expect the OEM (original equipment manufacturer) to be able to make adjustments quickly and accurately. This can cause headaches for the OEM when trying to spec, source, and build the equipment. The OEM may have already sourced a specific component for their equipment, then the customer changes their requirements, and the OEM has to go back to the drawing board and find a new source for that specific component.

The three most expensive words in an industrial equipment manufacturer are ‘Job change order” which is an indicator that something in the plan is out of step with the client’s needs. Having a thorough quoting process will hedge the impact of these to be sure, but job change orders can sink an otherwise profitable project if they’re not managed.

This equipment is hopefully in use 24/7, 365 so customers look to the OEM to ensure they are able to keep maximum uptime.

Many OEMs have not embraced the customization trend, usually because they lack an understanding of how additive manufacturing can help them. Aftermarket service and support departments utilize additive to produce those unique parts and in many cases has had a huge impact on that part of the business.

New Technologies

There is ongoing pressure in all of manufacturing to adopt new technologies. Modern industrial manufacturers are implementing tools to automate and track their processes to improve operational efficiency. They’re incorporating IIoT or, the Industrial Internet of Things, to provide customers with real-time performance, throughput, and quality assurance. Customers want to know exactly what their equipment is doing in real-time so they can identify errors quickly and make necessary adjustments on the fly. Digitalization has immense benefits to both customers and OEMs because of how easy it is to order replacement parts or services online or have it done automatically based on inventory, new orders, anticipated shortages, etc.. Customers get the visibility and control they require, and OEMs see cost savings by reducing the need to travel on-site.

Industrial Additive Manufacturing Equipment

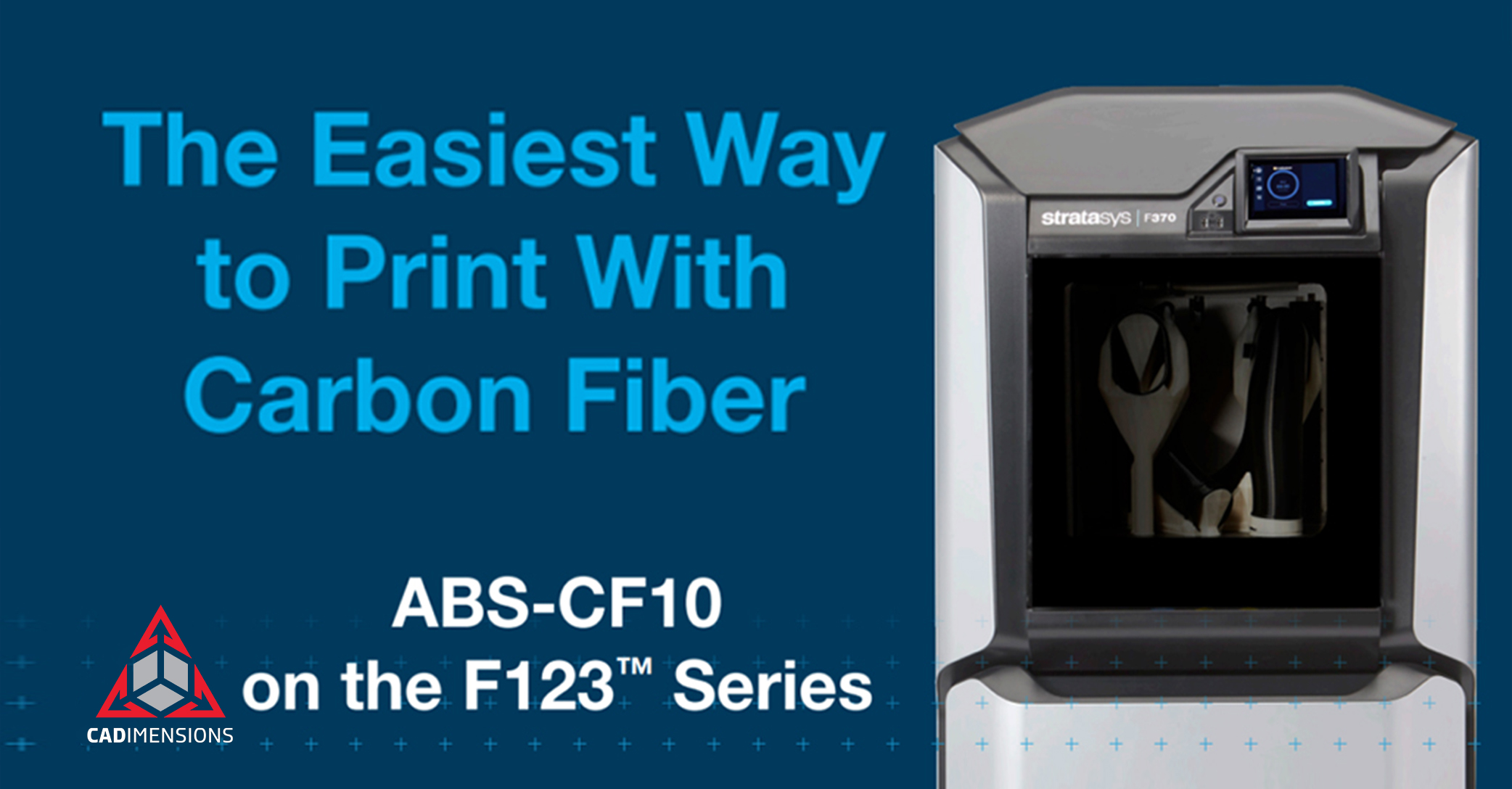

There is one industry that both supports machine factories and produces industrial equipment that is worth bringing into the conversation, and that is additive manufacturing. The additive manufacturing industry is technologically advanced and unique in that it allows for direct CAD to fabrication. It also integrates seamlessly into existing production environments, cloud or otherwise. The customization is limitless, whether it’s one part a day or one million unique parts a year, 3D printers are ideal. The OEM and community support is also next to none. There is a deep-rooted passion starting from hobby 3D printers all the way to industrial additive equipment. The community is constantly pushing the boundaries of additive through research and collaboration. Businesses that adopt additive are well-positioned to adapt quickly to changes in customer demands, allowing them to provide the exact solution their customers need.

There’s an easy ROI when you consider an OEM who can utilize additive to create custom components for their machines and have a catalog of replacement parts they can produce rapidly when needed.

We’ve seen an increased interest in additive technologies among equipment manufacturers, specifically with the recent release of the Stratasys Origin One and H350 3D printers. These two machines are capable of producing high volumes of unique parts in production-grade materials. This allows OEMs to have direct control over their supply line with the capability to produce their custom components in-house.

Manufacturing Agility

The primary focus of equipment manufacturers in the coming years, as new technologies are implemented and customer requirements become more strict, must be manufacturing agility. OEMs need to be able to adapt quickly to changes in customer demands and supply chain disruptions.