Why Pantone Validation is Huge for Stratasys 3D Printers

Stratasys recently became the first (and only) Pantone ® Validated 3D printing service provider. This means both the J750 and J735 printers can now 3D print in the Pantone-validated color palette. 1-Click validation of color matching allows designers to define print colors on products we use every day. This feature is available through a GrabCAD Print software upgrade at no cost to Stratasys J750 & J735 system owners.

What is Pantone and why is this a big deal for color 3D printing?

Pantone’s matching system, also known as PMS Color, provides a universal language for color to make sure 3d printer filament and resins are exactly what the designer ordered. It helps designers and manufacturers communicate the precise color needed for a product. Universal measurements are for more than time, distance, mass, and temperature. Having a universal language for color is nearly as critical. Like our previous article, products that are not to spec cost money and time.

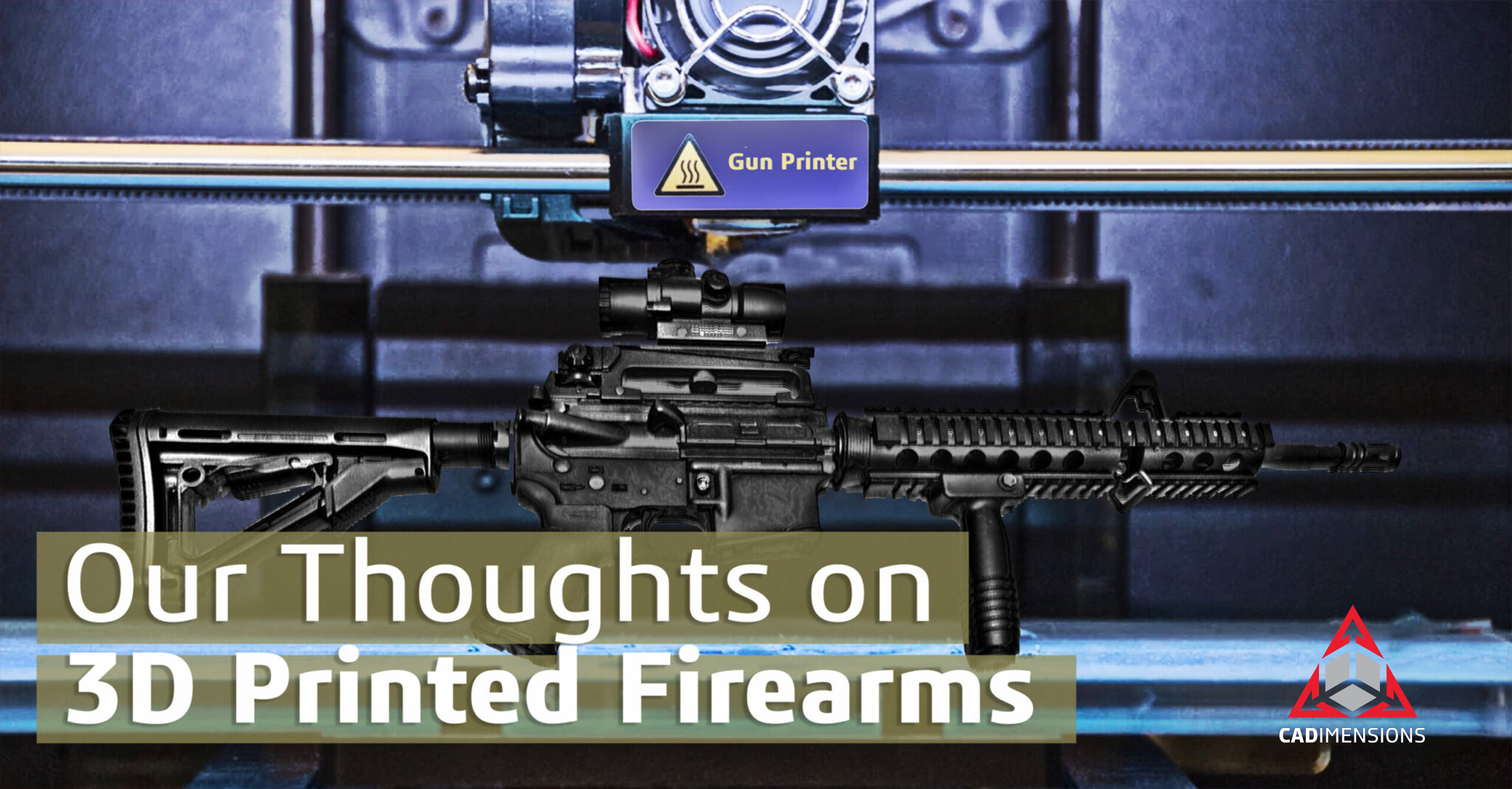

Why Color Consistency is Important. Especially with a Multi-Color 3D Printer

Context-dependent memories: When people don’t remember things without their original context. This can happen when colors are incorrect. For example, the thumbnail of the video shows a customer abandoning a product for one with more consistent branding.

Rapid Prototyping with Pantone Verification Is Awesome

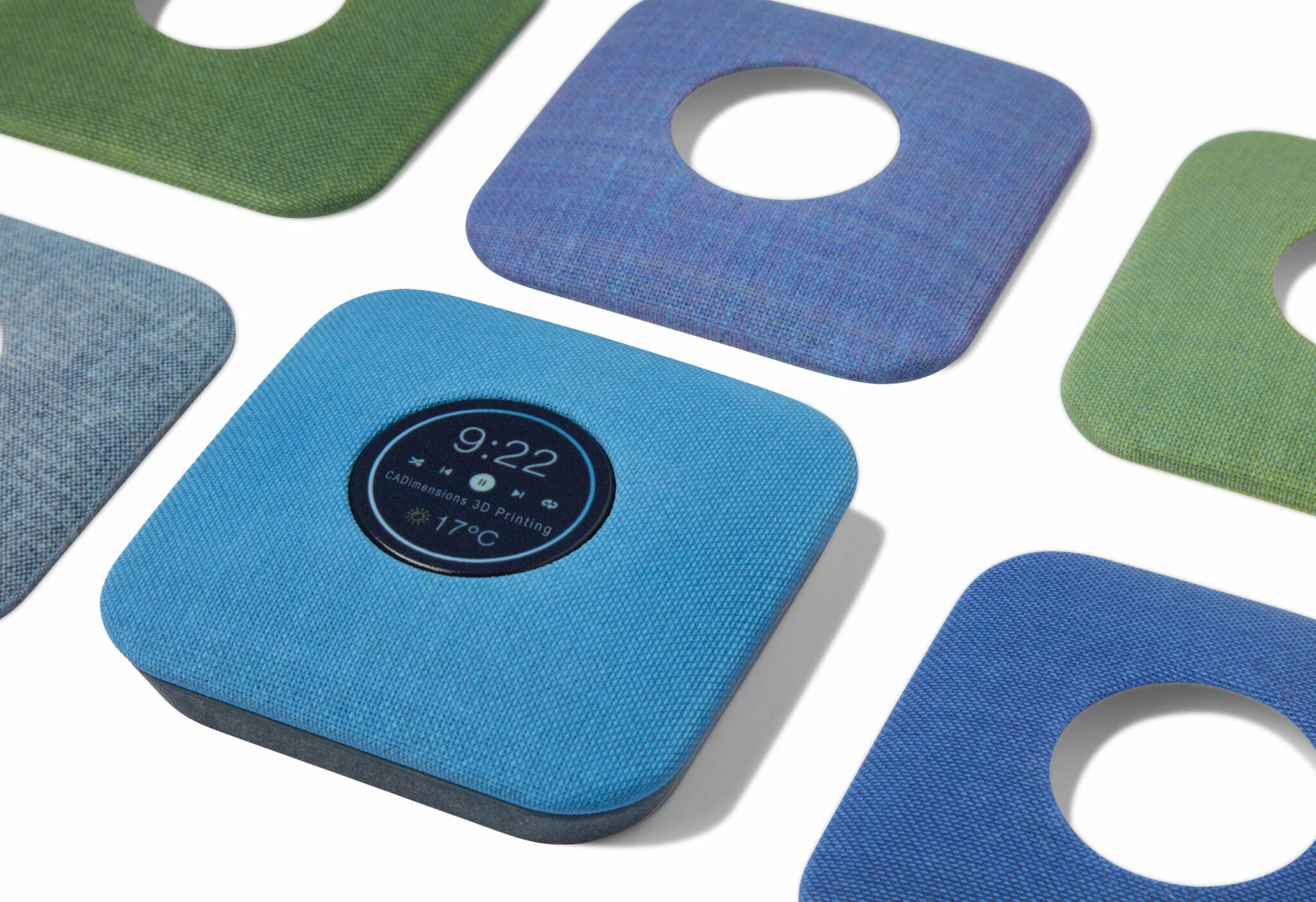

A few years ago, I had to inspect a printed design that I created. I expected the prints to be exactly to spec because I had sent them the Pantone color swatches and codes. Unfortunately, I had to send it back because the blue was too light.

It turned out to be a calibration error and there wasn’t a problem in the next round of samples. Still, we lost time because they didn’t have good quality control measures, even though I sent them the color code and a sample of the exact color. The great thing about the J750 and J735 is that I know they are already calibrated properly. With a few simple quality control measures, everything sent to a client will be color perfect.

Hand-Painted Prototypes Take Too Long

Hand-painted prototypes are still the industry standard. Rapid prototyping along with precise color accuracy from a color 3d printer makes prototyping a single-step manufacturing process while reducing the time and money spent on each prototype.

I look forward to all the future design uses for Stratasys now that they have adopted such a popular color management standard.