5 Common Injection Molding Problems & How to Avoid Them

The injection molding manufacturing process is a very common bulk manufacturing method due to its repeatability, reliability, and relatively low cycle time. However, like any design or manufacturing process, it’s not without potential pitfalls. Every new mold design presents new challenges for mold and part designers alike. Issues with the final product can be caused by part design, material selection, or mold design. Let’s take a look at 5 of the most common injection molding defects and how we can prevent them.

1. Weld Lines

Weld lines occur in plastic parts when two or more melt fronts come together and meet in the middle. This can happen when dealing with a part with multiple injection locations, or holes, or other geometry in the final product. These defects are not always purely cosmetic; weld lines are often the weakest point of an injection molded part because the melt fronts partially solidify when they collide, resulting in much weaker molecular bonding.

Some of the common fixes for weld lines include:

- Increase the resin temperature to ensure both sides of the weld line are liquid when colliding.

- Increase the injection speed to reduce the amount of cooling happening in the mold.

- Redesign the mold to prevent the weld line.

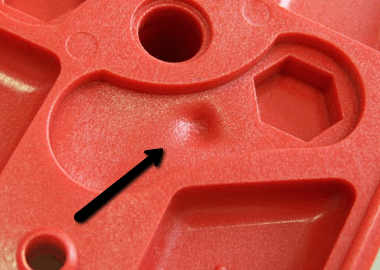

2. Sink Marks

Sink marks are areas of the plastic part that are recessed from the rest of the part due to uneven cooling while the part is in the mold. Once the melt front enters the mold cavity, it comes into contact with the mold wall and starts to cool, causing it to contract and pull away from the mold. These blemishes are purely cosmetic but still undesirable.

Some of the common fixes for sink marks include:

- Increase holding pressure to ensure the part makes good contact with the mold as it cools.

- Increase the cooling time to ensure the part solidifies in the proper spot.

- Design a part with thinner walls to decrease the amount of cooling time necessary.

3. Warping

Warping of plastic parts is also caused by uneven cooling as the part sits in the mold. As different parts of the plastic cool at different rates, they start to shrink and can introduce uneven stresses, bending moments, and torsion into the part, leading to deformations that were not expected when the part was originally designed. This can also cause some precision parts to be out of tolerance, leading to scrap and rework.

Some of the common fixes for warpage include:

- Make sure the part is cooling evenly to shrink evenly, not introducing any uneven stresses.

- Design the part with symmetry if possible to stabilize the cooling.

- Lower the temperature of the melted plastic to reduce cooling needs.

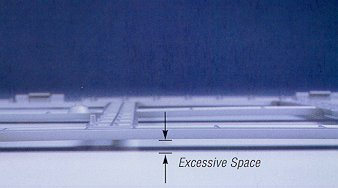

4. Air Traps

One of the more serious defects in injection molding is the creation of air traps in the finished part. These air bubbles can result in structural and cosmetic defects when the air that’s originally in the mold has no exit and gets absorbed into the finished part. If the air in the mold gets compressed tight enough and hot enough, it can actually explode, damaging both the mold and the finished part.

Some of the common fixes for air traps include:

- Shorten the cycle time to ensure trapped air doesn’t have time to compress and ignite.

- Raise the injection pressure to force trapped air out of the cavity.

- Choose a material with lower viscosity to limit air bubble formation.

5. Short Shots

The most crippling issue when dealing with injection molding is the short shot or an incomplete fill of the plastic part. These parts are not only cosmetically incorrect, they are almost 100% scrapped and have to be redone. These issues can lead to the mold being recut or reworked, expensive project delays, and massive financial and productivity losses.

Some of the common fixes for short shots include:

- Redesign the mold with bigger gates to allow for a smoother flow.

- Keep the mold wall temperature hotter to ensure the resin remains viscous enough to fill the cavity.

- Increase injection pressure to fill the cavity faster.

Predicting these issues before they happen.

Fortunately, SOLIDWORKS Plastics allows for the analysis of parts that are going to be injection molded to screen for all of these defects and more. We can check for short shots, injection pressures, weld lines, air traps, sink marks, and warping! Reach out to us if you think Plastics will help your workflow and let’s design better parts together!