5 Ways Design Validation Will Save Money

Designers and engineers today face different challenges than did their counterparts from even 10 years ago. Even the term “design validation” has a completely different meaning. One of the biggest questions in today’s design process revolves around prototypes. Companies today have to wait on physical models to be created before they can test for failures. This process is slow, expensive and entirely unnecessary. Finite Element Analysis (FEA) uses mathematics to apply real-world conditions to your design, and smart designers use it as a tool throughout the entire design process.

If we look at just the top 5 ways design validation can save companies money, you can see pretty quickly how valuable a tool it can be. It’s so much more than just the time it takes to create a prototype! Engineering dollars are wasted every single day when FEA is not a part of the design process. Let’s break down every part of that process and how concerning yourself with only prototypes is negatively affecting your business.

1. Design

Using design validation starts where you do, at the design stage. According to Engineering.com, “up to 80 percent of the cost of a product’s development is determined by the decisions made early in the design process”. This means that decisions made early on will significantly impact the cost of the product. The overall cost of development will also determine the end user cost. Keeping development costs down can ultimately increase margins while keeping prices competitive.

Why go through the trouble to design and generate a prototype relying only on the “rule of thumb” or the “hope and pray” method? Why spend all of that time and money creating a model and prototype without knowing its failure points or limitations? How can you innovate with that mindset?

Implementing FEA into your design process will allow designers the ability to test and change the product on the fly! This greatly accelerates your product development process. Using good analysis coupled with the ability to change on the fly will reduce the need to manufacture prototypes. In return, this saves time, money, and can increase margins due to overall lower developmental costs.

2. Prototypes

FEA should not replace prototypes but in fact, compliment the process. According to this Aberdeen study, “The prototype stage is merely used to validate that the product is error free, not to actually find errors.” You should not be waiting for a prototype to determine if the product is going to fail! The role of the prototype should be only to validate that it holds up to specifications through your manufacturing process. In that same study, 65% of respondents stated that the “top challenges of physical prototypes are the time and cost required to build them.” Reducing the number of prototypes in the design process by implementing design validation can greatly reduce those challenges. 50% of respondents also complained that “multiple iterations of prototypes are needed.” It’s never as simple as building one prototype, right?

FEA reduces the number of prototypes needed because it can perform on-the-fly testing and product validation in a virtual space. By incorporating design validation into the process, the three major challenges in this study can be greatly reduced. All of which makes hitting the deadline and budget much easier.

3. Testing

Testing is one of the most time-consuming parts of product development and when failures occur, changes have to be implemented. Not to mention that outsourcing the testing is costly and bringing it in-house requires expensive machinery. Analyzing why the part failed, where it failed and how to fix it takes time. The actual testing procedure takes time due to the wide-ranging types of studies. Testing can also be limited based on the availability of specific machinery. You might also need to create specialty fixtures just to adequately represent loads seen in the real world. All of this not only takes up precious time but costs money.

Using FEA won’t directly change all parts of the testing process but, offloading some of that testing virtually reduces the amount of physical testing required. Testing will still be necessary at the very end to verify that everything works as designed. Applied Abstractions said in this article that “a prototype is something you build to see whether something will work, and a simulation is something you build to see whether something will break”.

4. Revisions

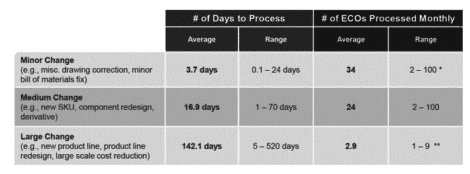

Engineering Change Orders (ECO’s) are a result of analyzing the test data and determining that a change is required. A reasonably complex change request comes in, let’s say it’s a component redesign. This change will take an average of 17 days to be completed from the time the request is made. If you could eliminate just one ECO per project it would save three weeks of time. Can you imagine how much time that is worth? Did you know that 73% of organizations don’t even know the actual cost of engineering change orders?

Using FEA allows you to identify weak areas of a component on the fly before an ECO is requested. The ability to adjust your model while designing it can reduce the number of revisions and ECO’s which save time, money and rework.

5. Field Failures

Even with the most rigorous testing, it’s still not uncommon for a part to fail in the field. When that happens a recall could be on the horizon and eliminating any future impacts on the customer should be the number one priority. When a field failure occurs you must identify how and why it failed and begin testing to see if it can be reproduced.

A revised part is already in the works but first, reproducing the problem in testing is critical. One way to be sure you’ve eliminated the failure is to confirm your changes in a physical prototype. With FEA it’s very easy to make changes and verify if it’s stronger than the previous revision. You can even use certain technology in FEA that will automatically change your design to increase the factor of safety based on variables and goals. The process of using FEA can make revising a part in the field much easier and quicker, allowing the customer to get back running and certain that there will be no issues moving forward.

Incorporating design validation from the start results in fewer field failures because there can be more extensive and unique testing within the same time frame as the physical testing. By virtually testing more thoroughly using FEA, designs will be better and less prone to failure.

Improving the design process by using simulation is something we preach a lot. Check out this video that goes over how you can benefit from incorporating simulation to improve your product lifecycle.