Functional Prototyping: Bringing Ideas to Life with Purpose and Precision

An Essential Milestone in the Transformation of Ideas

Functional prototyping serves as a vital step in the journey from concept to market-ready product. Functional prototypes provide a physical representation of the final product’s form, fit, and useability – allowing designers to test, validate, and refine their designs. This blog will define functional prototyping, its benefits, and how it plays a vital role in launching innovation and delivering cutting-edge products.

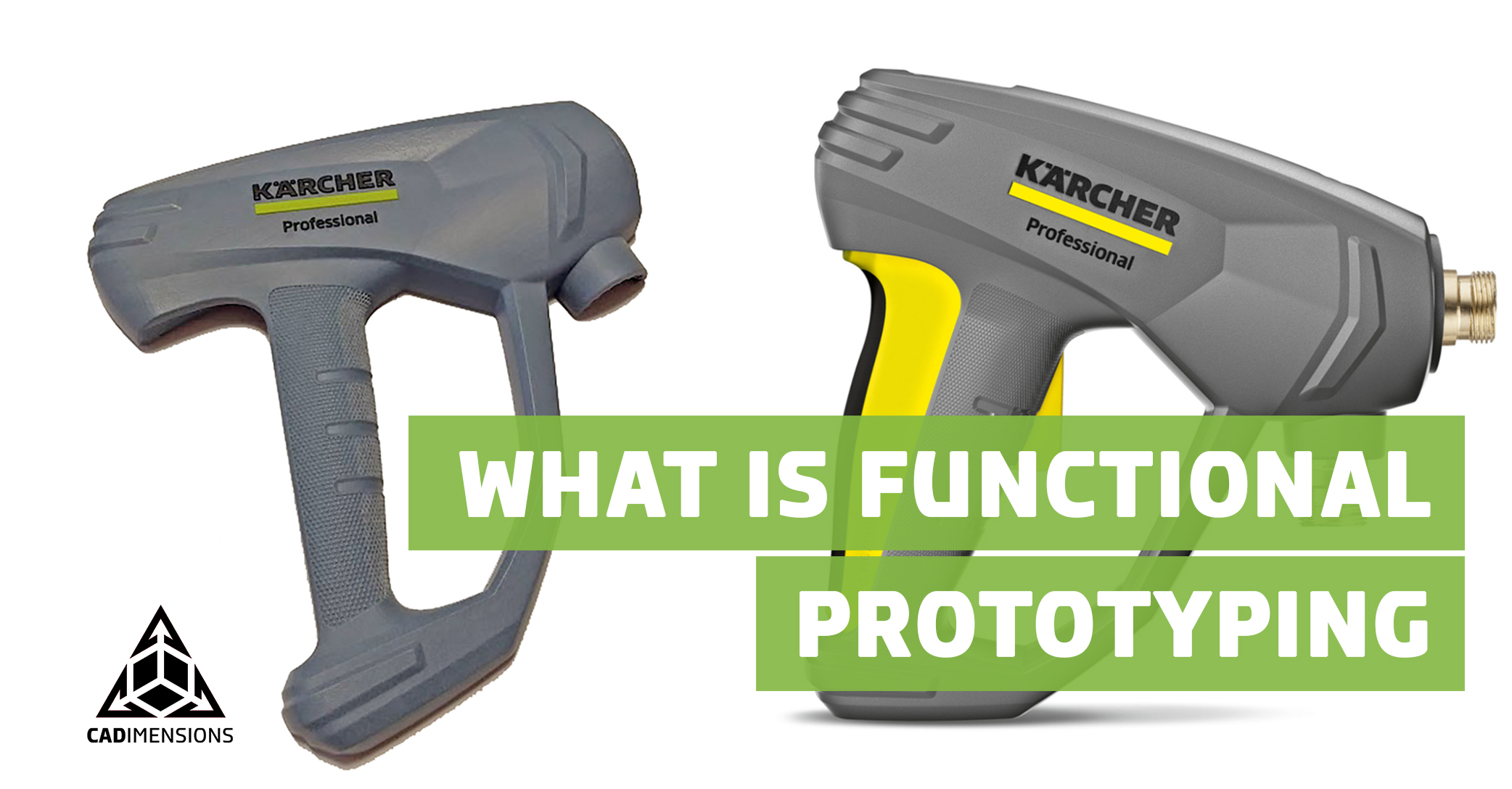

What is Functional Prototyping?

This form of prototyping involves the creation of physical prototypes that closely mimic the final operation of a product. These prototypes are built using materials and manufacturing processes that replicate the intended performance and characteristics of the end product. Functional prototypes aim to test and validate the useful aspects of a design, ensuring that it meets the desired requirements and specifications.

Purpose and Precision

3D printing technologies offer exceptional precision, allowing designers to replicate intricate geometries, fine details, and obscure features with remarkable accuracy. This precision ensures that the functional prototype accurately represents the intended design, enabling designers to evaluate its practicality. The purpose is to validate and refine the design, test its effectiveness, gather user feedback, and optimize the product before mass production. By combining precision and purpose in functional prototyping, designers can achieve greater confidence in their designs, streamline the product development process, and deliver high-quality products that meet the intended purpose with precision and efficiency.

So Why Functional Prototyping?

Since functional prototyping allows designers to validate their design concepts, identify and resolve issues early on and optimize the features and performance of the final product – this leads to faster iterations and reduced time to market, which ultimately results in companies saving costs and staying ahead of competitors. The ability to customize and personalize prototypes caters to individual user needs, while improved collaboration and user feedback ensure alignment and enhanced user experiences. Additionally, functional prototyping encourages innovation, mitigates risks, and facilitates market validation, resulting in products that meet customer expectations.

Reach Unprecedented Levels of Achievement

In conclusion, functional prototyping in 3D printing revamps the product development process by providing designers with a powerful tool to bring their ideas to life with precision and purpose. By harnessing the capabilities of 3D printing for this form of prototyping, designers can unleash their creativity, explore new possibilities, and transform cutting-edge ideas into tangible realities. The power of functional prototyping lies in its ability to bridge the gap between imagination and execution, propelling the world of product development toward new heights of innovation and success.