College Students Need 3D Printing Experience

Design & Manufacturing Students Need 3D Printing Hands-On Learning

Mass-produced products have been made with methods like injection molding, casting, and machining for the entirety of the industrial age. However, a handful of 3D printing companies are aiming to change that, and making additive manufacturing a cost-effective option to create end-use products.

Businesses that design and manufacture products will need designers and engineers who understand 3D printing in order to take advantage in this shift away from traditional mass production methods.

3 Examples of 3D printing Technology that will Replace Conventional Manufacturing

Skeptical? That’s totally fine. Here are some examples of technologies to persuade you, though we want to stay focused on why it’s important for students.

Stratasys Continuous Build 3D Printer Cell

Stratasys LPM Metal 3D printer

This 3D printer is designed to make mass production of small metal components possible, with no tooling requirements. The process combines additive manufacturing with press-and-sinter powdered metallurgy.

Desktop Metal Production System

The Desktop Metal Production system is another example of mass manufacturing-focused metal 3D printing. This machine combines binder-jet 3D printing with metal injection molding.

These examples are only from the products we represent. HP, Carbon, and Formlabs - among others - are aiming to disrupt conventional manufacturing practices.

The Importance of Hands-On 3D Printing Experience for Students

The technologies mentioned above are available today or will be within the next few years. Businesses will start to see the benefit of using 3D printing on a large scale, but only if they have a workforce that can design products optimized for it.

Hands-on participation enables students to retain 75% of the information presented, compared to only 5% when a lecture is given.

Source: 7 Benefits of Incorporating Hands-On-Learning into Your Classroom Training

Designing for any manufacturing process can be challenging, and 3D printing is no exception. Hands-on learning is by far the best way to teach this skill. Hands-on participation enables students to retain 75% of the information presented, compared to only 5% when a lecture is given.

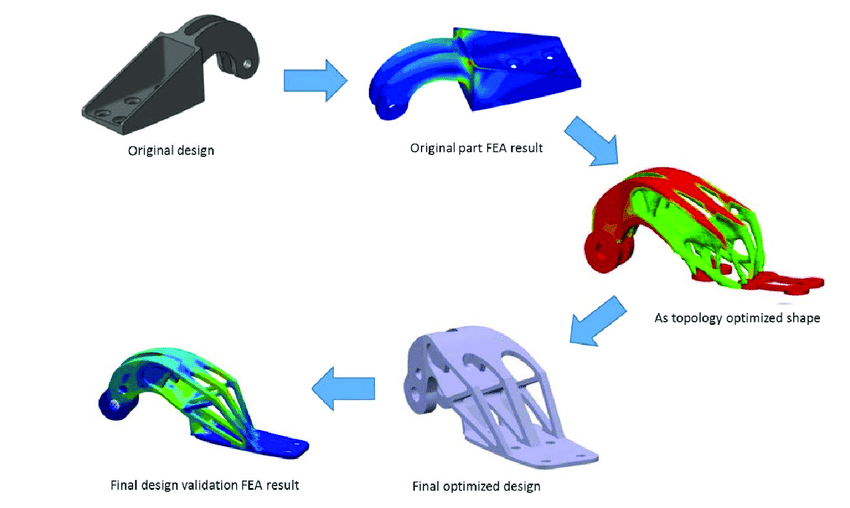

The image below shows what a conventionally-designed part might look like. When you compare it to the final design – optimized and designed for additive manufacturing – the difference is staggering. This design ability will be in high demand sooner than we know it.

The Next Step for Manufacturing

Additive manufacturing will disrupt conventional methods of mass-producing products sooner than we can imagine. There are additive technologies available today that can compete with well-established production methods, and more are becoming available every day.

Businesses will need a workforce capable of working with 3D printers, and hands-on learning is the best way to educate students. Further, failing to educate students on 3D printing is setting them up to disappoint their future employers.

Looking for a prime example of a school at the forefront of additive manufacturing? SUNY New Paltz is a must-see.