SAF™: A New Production Technology From Stratasys

Stratasys has announced a brand-new technology: Selective Absorption Fusion (SAF™). Spoken ‘saf’, this technology signifies Stratasys’ entry into the powder bed fusion market. Powder bed fusion (PBF) is the fastest-growing polymer segment of additive manufacturing today and is driving it to the next level. SAF™ technology will power the new H Series™ 3D Production Platform from Stratasys.

SAF™ Background

Stratasys has spent over 10 years researching and developing powder bed fusion and has been establishing relationships with leaders in additive manufacturing technologies. More recently, in July of 2018, Xaar PLC and Stratasys announced a partnership in a newly formed company, Xaar 3D Limited, to develop 3D printing solutions based on High-Speed Sintering technologies. Xaar is the world’s leading independent manufacturer of piezo-based drop-on-demand inkjet technologies. Their technology is used in a wide range of manufacturing applications such as graphics, labelling, product decoration, and most importantly, functional fluids for advanced manufacturing techniques. Xaar has an extensive printhead portfolio and easy to integrate system components like drive electronics and ink supply systems. These investments have enabled Xaar 3D Ltd to accelerate the development of its additive manufacturing solutions. Fast forward to March 2021 and we now have the result of this venture: SAF™.

SAF™ Process

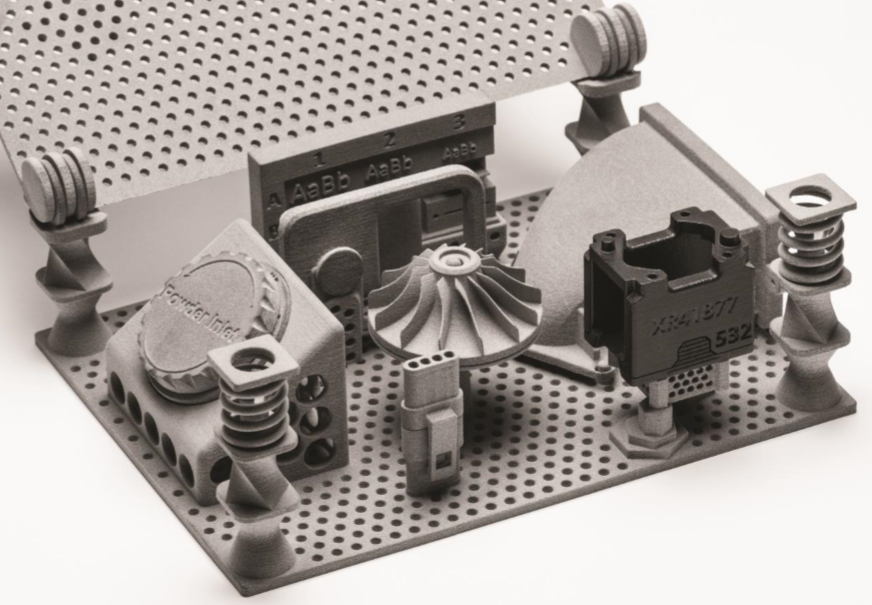

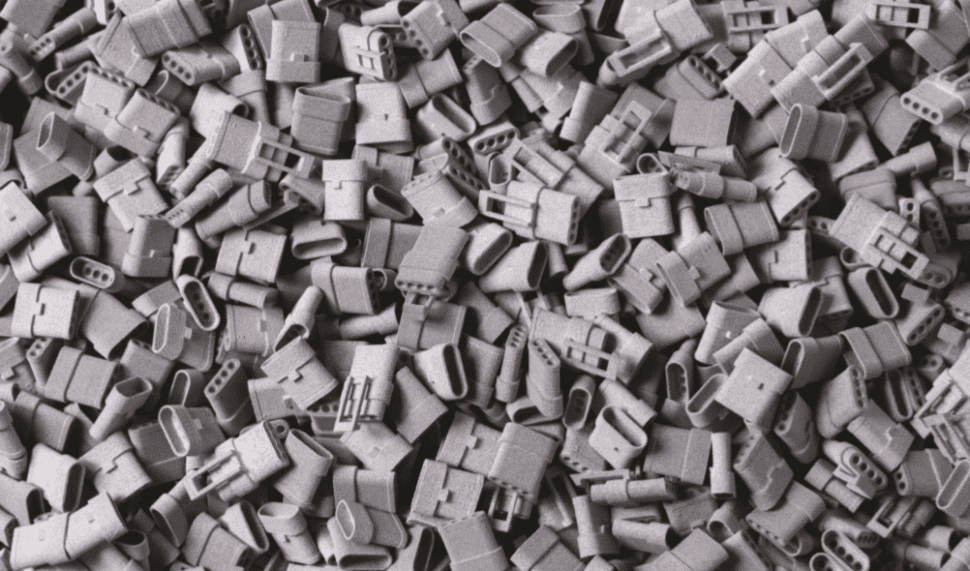

So how is SAF™ different from other PBF technologies? The differences between SAF™ and other PBF technologies will come down to how it is implemented in a new machine. SAF™ uses an infrared sensitive HAF™ (High Absorbing Fluid) to fuse particles of polymer powder together in discreet layers. Stratasys has developed a proprietary powder management system called Big Wave™ that uses a counter-rotating roller to evenly distribute powder across the entire bed. Industrial-grade Piezo-electric print heads jet the HAF™ in precise areas, then exposure to infrared energy causes the areas with HAF™ to melt and fuse together. These key processes are all executed in the same direction across the print bed. Unlike other PBF technologies, SAF™ uses a one-pass print-and-fuse process which results in consistent parts regardless of their placement in the build. SAF™ will offer real-time powder heating, unique thermal management and broad powder range for a wide spectrum of part properties. Stratasys has not revealed all of the details of how the H Series™ Platform will operate, but it is expected to be an improvement over other PBF machines available today.

SAF™ Applications

SAF™ is an industrial grade technology with a high production throughput. It excels at end-use parts that can be mass customized at a low cost per part. Hundreds of parts can be nested in a single build tray to achieve true production-level quantities. Industries that would take full advantage of SAF™ include automotive, aerospace, defense, and any manufacturer seeking accurate, consistent production at competitive part costs.

What’s Next?

Stratasys has announced their plans for the H Series™ Production Platform but has not revealed the details of a new machine. Commercial availability of 3D printers based on SAF™ technology is currently expected in the third quarter of 2021. We will have to wait a little longer to see SAF™ in action.