How Startups Make Their Designs Into Products. Fast.

The Goal: Being able to touch your product design, hold it, use it, and most importantly, share it with the world… at a profit of course!

It always starts with a good idea. A new approach to something old, an old approach to something new, or simply one of those “How has no one come up with this before?!” moments. From the second the spark of inspiration strikes, it ignites a fire in you to bring that idea to life.

Once you’ve found that original idea, the first step is to find funding so you’re able to take that idea and get to that shining beacon on a hill…a working physical prototype (cue harp music). Your concept, as a tangible thing that you made come to life. Long before that, you will need to answer some pretty heavy questions to prove your product is viable. They could be questions like:

- Am I going to make this my business, or license it to someone else?

- What material(s) will this be made from?

- How much funding will I need to get a prototype built?

- How many units can I manufacture?

- How much will it cost me to make this?

- Will this do what I expect it to do once it’s built out?

- How might it break?

- It goes on, and on…

Where to even begin with your product design?

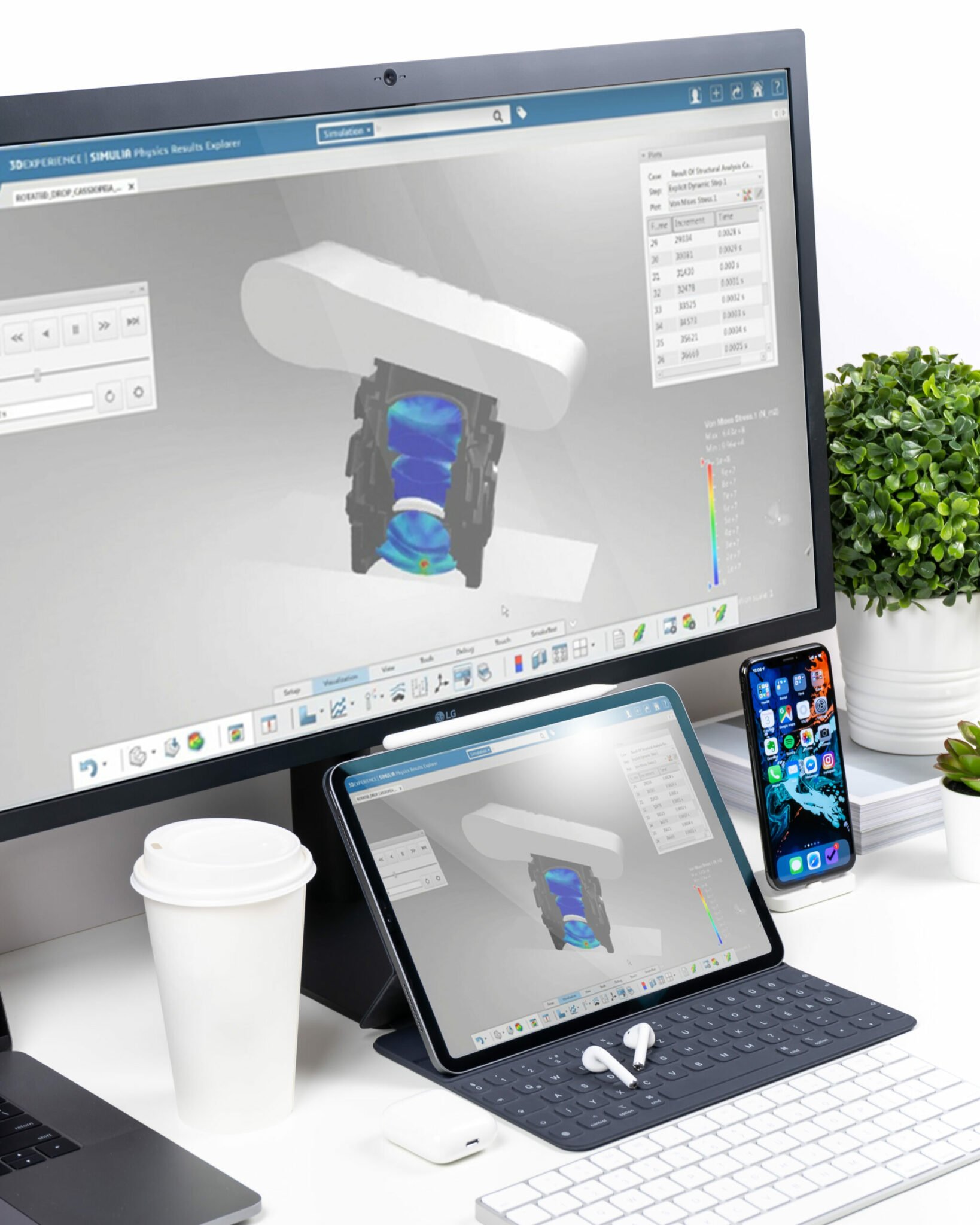

You’ll start small and easy but quickly learn that to make this happen, you will need someone in your orbit who can design your 3D model and get the ball rolling. In a nutshell, you need to take your idea and create it in a 3D space where you can build out the individual components that make up your product design. Everything from screw holes to flow valves can and should be represented in your model in a way that makes it as easy as possible to produce. Once you have your idea captured digitally and in 3D, a world of opportunities opens up to you. First and foremost, once in 3D prototype form, any necessary or beneficial design changes can become apparent that would enhance the product or reduce manufacturing costs. Finding out a critical design change before you go to market can really save a lot of headaches, and money!

Where to next?

The second most important reason is, 3D models can be used to create patent drawings and views, which can be expensive and are commonly needed for new product designs. But this is literally the tip of the iceberg. Other benefits of working from a 3D CAD model include:

- Understanding the working mechanics of your product.

- Simulate how your product will respond to being dropped onto different surfaces or react to excessive heat or pressure.

- Understand where you might have wearable parts that will need to be replaced - how often, and after how much usage.

- Design housing and routing for electronic components.

- Use digital renderings to create marketing or licensing material.

- Have a common file format you can share with manufacturers to get quotes on production. (This also provides you and your investors with cost estimates for future budget planning).

- Do anything that comes after having an idea in the first place!

Designing a product, making it manufacturable, and getting it to market is not easy, even with the right skills, experience, and software programs to help, it’s just not an exact science.

“I have not failed 10,000 times. I’ve just found 10,000 ways that won’t work.”

-Thomas Edison

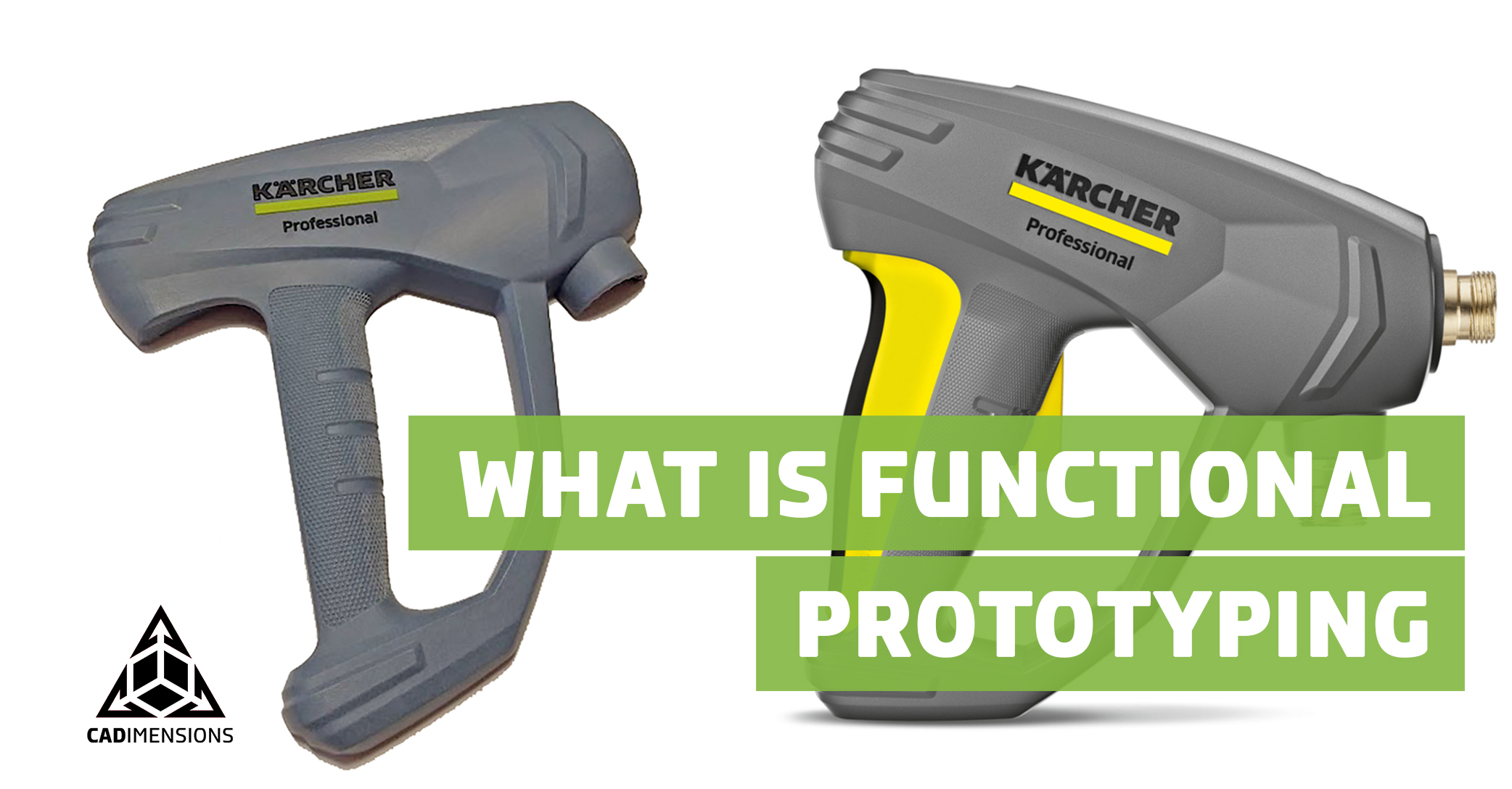

Once you finally have a 3D model and a working physical prototype, you can pitch your idea to investors on the next round of funding. Add some eye-catching renderings of your product in use in the real world and drive home the concept. Say it loud, “Here it is, my great idea! It will change the world for those who use it, and your money will make it happen!” (cue the confetti cannons).

Phew! Let’s stop and take a deep breath, shall we?

To be honest, that all sounds exhausting, and for some, even intimidating. The good news is, CADimensions has the staff, software, and experience to help you with literally every single step in that process. From modeling a concept to producing a showroom-ready finished prototype, we can help you right along your journey to success.

Working with us, companies big and small have been able to reduce the time, energy, and resources used to bring products to market or launch revisions. Every project is unique, and we thrive on the challenges we see every day.

We are always open to confidential conversations about your next big idea and how it will change the world around us. We are your partner in design solutions.